Alex_M

Full Access Member

- Joined

- Sep 27, 2021

- Posts

- 376

- Reaction score

- 678

Hey all! I purchased a buddies 97 Suburban K2500 7.4l. He had issues with it the four years or so he owned it. I'll say up front, my question is - what is required to swap a reman ecm?

History is as follows, for those interested and for a differential diagnosis if anyone has one. Buddy bought the thing and he had issues with an intermittent miss. Fairly regular (cutting in and out) above 3500-4000 rpm irregardless of load. Also happens at sustained ~2500rpm. Seems to be irregardless of load - it does it in neutral or driving about the same. Buddy tried plugs, wires, and cap/rotor. That didn't work so he figured it was a fuel issue. He replaced injectors, fuel pressure regulator, fuel filter, and fuel pump (twice?). He also replaced O2 sensors and crank position sensor at some point throughout all this. I felt it was more of an ignition issue as harshly as it would cut out, and the tachometer would dive when it happened. I replaced the coil and ignition module, no change. Also a consistent issue on hot restart with missing/poor running for the first 30-45 seconds. Changed the distributor and also no change.

Since I've had it the only code it has had is a Bank 2 lean code, but there is an exhaust leak on that side that I believe is causing that - I've not gotten the gaskets I ordered in yet to fix. Also just a note, AC isn't working and yes, all fuses have been checked.

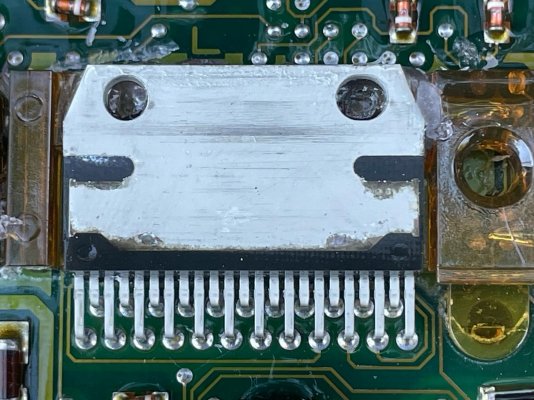

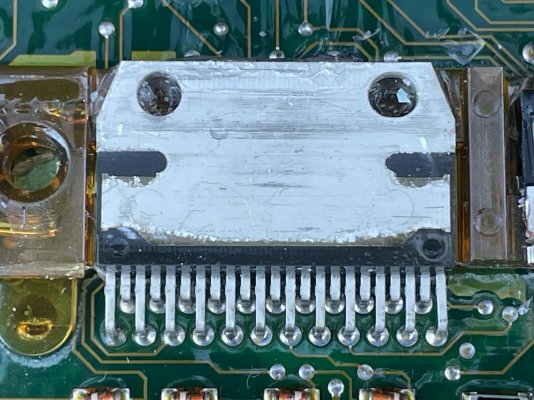

At this point I am thinking it's an ECM issue, so today I pull the ECM to crack it open and just see if I can tell any obvious issues. No bad resistors or capacitors that I can see. No burnt spots on the board. One of the connectors where it connects to the board looks to be cracking but the other side is solid where it connects. A couple of the chips seem a bit discolored to me. I'll post pictures below. I clean up the original thermal pads and reapply new thermal compound to all the chips and mosfets that use the case for heat dissipation. Close it back up, throw it back in, truck won't start. No fuel pump. I jump the relay manually and the pump runs. Truck fires up, missing and throwing white smoke. Interesting note, the AC is now working, but the truck is running very poorly and I now have a new code - P1345 Camshaft to Crankshaft Position Correlation Fault. At this point I feel fairly confident in the ECM diagnosis, feeling the issue is too consistent for a wiring problem, and not knowing of anything else it might be. However, if you have another idea I am all ears.

So that leads me back to my original question - what is requried to swap in a reman ecm? They say they have to be programmed - is that something the dealer has to do or can I do a relearn procedure at home?

Thanks!

Alex

History is as follows, for those interested and for a differential diagnosis if anyone has one. Buddy bought the thing and he had issues with an intermittent miss. Fairly regular (cutting in and out) above 3500-4000 rpm irregardless of load. Also happens at sustained ~2500rpm. Seems to be irregardless of load - it does it in neutral or driving about the same. Buddy tried plugs, wires, and cap/rotor. That didn't work so he figured it was a fuel issue. He replaced injectors, fuel pressure regulator, fuel filter, and fuel pump (twice?). He also replaced O2 sensors and crank position sensor at some point throughout all this. I felt it was more of an ignition issue as harshly as it would cut out, and the tachometer would dive when it happened. I replaced the coil and ignition module, no change. Also a consistent issue on hot restart with missing/poor running for the first 30-45 seconds. Changed the distributor and also no change.

Since I've had it the only code it has had is a Bank 2 lean code, but there is an exhaust leak on that side that I believe is causing that - I've not gotten the gaskets I ordered in yet to fix. Also just a note, AC isn't working and yes, all fuses have been checked.

At this point I am thinking it's an ECM issue, so today I pull the ECM to crack it open and just see if I can tell any obvious issues. No bad resistors or capacitors that I can see. No burnt spots on the board. One of the connectors where it connects to the board looks to be cracking but the other side is solid where it connects. A couple of the chips seem a bit discolored to me. I'll post pictures below. I clean up the original thermal pads and reapply new thermal compound to all the chips and mosfets that use the case for heat dissipation. Close it back up, throw it back in, truck won't start. No fuel pump. I jump the relay manually and the pump runs. Truck fires up, missing and throwing white smoke. Interesting note, the AC is now working, but the truck is running very poorly and I now have a new code - P1345 Camshaft to Crankshaft Position Correlation Fault. At this point I feel fairly confident in the ECM diagnosis, feeling the issue is too consistent for a wiring problem, and not knowing of anything else it might be. However, if you have another idea I am all ears.

So that leads me back to my original question - what is requried to swap in a reman ecm? They say they have to be programmed - is that something the dealer has to do or can I do a relearn procedure at home?

Thanks!

Alex

Attachments

Last edited: