Just Fishing

Can't fix stupid

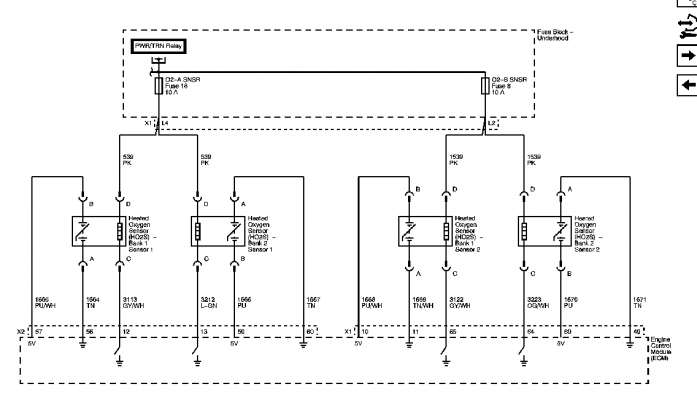

More on that code from the FSM,

P2271

• DTCs P0036, P0037, P0038, P0137, P0138, P0140, P0141, P0443, P0458, P0459, P2232 are not set.

• The Ignition 1 Signal parameter is between 10-18 volts.

• The Engine Speed parameter is between 500-5,000 RPM.

• The MAF Sensor parameter is between 3-50 g/s.

• The Vehicle Speed parameter is between 24-132 km/h (15-82 mph).

• The Fuel Level Sensor parameter is more than 10 percent.

• The Loop Status parameter is closed.

• The engine run time is equal to or more than 5 minutes.

THEN

• DFCO is active.

• The APP is stable.

• The TCC is locked.

• DTCs P013A, P013C, P013E, P014A, P2270, and P2272 have run and passed.

• DTC P2271 runs once per drive cycle when the above conditions are met.

P2271

The ECM does not detect an HO2S voltage less than 150 mV before accumulated mass air flow exceeds 550 grams

P2271

• DTCs P0036, P0037, P0038, P0137, P0138, P0140, P0141, P0443, P0458, P0459, P2232 are not set.

• The Ignition 1 Signal parameter is between 10-18 volts.

• The Engine Speed parameter is between 500-5,000 RPM.

• The MAF Sensor parameter is between 3-50 g/s.

• The Vehicle Speed parameter is between 24-132 km/h (15-82 mph).

• The Fuel Level Sensor parameter is more than 10 percent.

• The Loop Status parameter is closed.

• The engine run time is equal to or more than 5 minutes.

THEN

• DFCO is active.

• The APP is stable.

• The TCC is locked.

• DTCs P013A, P013C, P013E, P014A, P2270, and P2272 have run and passed.

• DTC P2271 runs once per drive cycle when the above conditions are met.

P2271

The ECM does not detect an HO2S voltage less than 150 mV before accumulated mass air flow exceeds 550 grams