Matthew Jeschke

Full Access Member

I bought that big trans cooler from trucool. It works AWESOME, but fits like $heet. A guy makes a metal bracket to mount it which is most of the job but needs spaced out from core support as ambient air sensor rubs on condenser and the trans lines fit like CRAP. You have to tweak the trans cooler lines as is to kind of fit it. Return line is too short and supply line is too long.

I'd like to fashion new ends for that line set but I cannot figure out how to make the quick disconnect flare. Anybody know how? Where do you get a tool to do that?

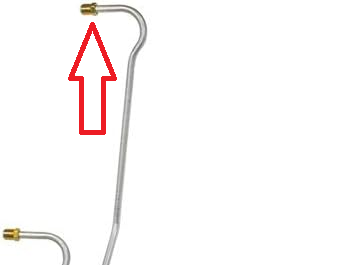

The flare like you see here...

Which fits into the Quick disconnect

I'd like to fashion new ends for that line set but I cannot figure out how to make the quick disconnect flare. Anybody know how? Where do you get a tool to do that?

The flare like you see here...

Which fits into the Quick disconnect