This is the kind of stuff I am talking about. There is always that risk of self-inflicted problems that crop up when you try to tackle things proactively. And for those situations, i like to have no time pressure.

My hurdle was finding the right gasket set for my VLOM. I went through HELL. Bought like 3 different kits that were all WRONG. Last kit I bought was right but required the rivets to be drilled out of the plate that hold the solenoids in place. BTW if you order the wrong gasket, many places refuse to return them as was in the case for ALL of mine.

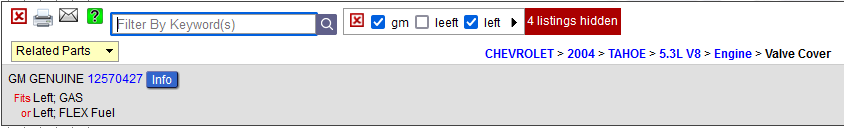

I hard to break down and order the complete VLOM assembly. In hindsight I am glad I did. It ran so much better afterwards too. Also plan on replacing the steam pipe crossover gaskets, oil pressure switch and screen. Much easier to do those while it is apart.

My main hurdle besides my huge hands trying to fit in the tight spots as getting the fuel line on the rail to disconnect. My disconnect tools were useless and I wound up damaging the lock retainer thing that goes over the o-ring seal.

And there is tons of cleaning to do as well so have plenty of brake cleaner and rags. And a shop vac. There is foam padding under the intake vermin like to make a nest out of. Makes amess. I left the foam off of it when I reassembled.

I also bought a roll of that absorbent padding to lay out on the work bench. Works great for cleaning up the intake and beats trying to work in a drain pan and spilling shit all over the place.