So my wife left me home, unsupervised this evening. I went the the garage to poke around a bit and maybe probe a couple LCM pins, before making myself dinner. She came home around 7:30pm, while I was still in the garage, dropped off the all weather floor liners she got me for Christmas, laughed when I told her I would be in shortly and is now asleep. I'm writing this as I'm making dinner, at nearly 11:30pm.

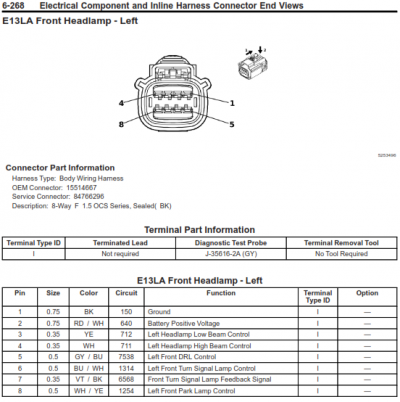

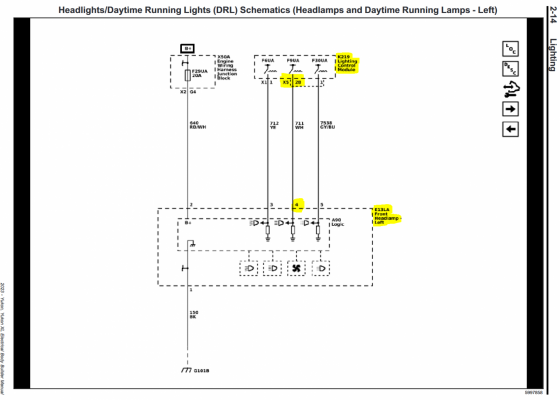

I wasn't able to probe the LCM pins of interest from the back side of the connectors with the probes I have at home. I think I could with the needle like probes we have a work, but I'm not going to the office until Tuesday and I was fairly confident I wanted access to these signals, so I tapped X3-7 (right backup light) and X5-16 (right high beam). There are left side equivalents to both of these but these where slightly more accessible in my truck. X5-16 measured 11.7V with the high beams on and truck not running, which is fairly close to battery voltage. Touching the tap to a generic automotive relay cycled it without any error messages so I proceeded to wire 2 relays with flyback diodes.

The high beam relay powers the switch I previously installed for driving lights, resulting in "off" and "on with high beams". I want "off", "on with high beams" and "on" which will require a different (or second) switch. The reverse light relay has no load connected as I haven't purchased (or decided on) lights yet, but it cycles with reverse gear selection.

I've drove 20 minutes after buttoning this up (and looking for any takeout restaurant still open) with high beams on about half that time. Everything works as expected and no error messages.

I'm going to look for a cargo light tap point near the back of the truck, as I don't see any reason to have them switched from the dash.