goldata81

TYF Newbie

- Joined

- Feb 18, 2010

- Posts

- 15

- Reaction score

- 30

Sorry this post got longer than I was planning....

So I've been dealing with a few error codes the past 2 months... P0121, P0171 and P0174 on my '07 Yukon Denali with 113k. Vehicle is completely stock besides a K&N air filter that I've had on for about 60k. There has been no engine work ever done. New plugs and wires at 100k. I've been logging OBDII data looking for a trend to point me in the right direction for a fix the past 2 weeks. The long term fuel trims max out at just over 24% under moderate to heavy acceleration but range about 0 to 5% at idle. MAP and MAF values appear normal(MAF is 6-8 g/s at idle) but I am not sure what they really should be. Commanded throttle and relative throttle position track each other nicely. Fuel pressure is 60 psi at idle, I haven't had a chance to check under heavy acceleration. I have taken my logged data during a few brief WOT runs and have calculated about 62% volumetric efficiency. I can't seem to find any info on what VE I should be expecting. To me, ~62% seems low?

This past weekend, I cleaned the MAF sensor and reran a WOT run today and now see about ~72% VE and my LFTF are about half of what they were before I cleaned the MAF and I haven't had any codes pop up over the last 3 days. The P0171 and P0174 lean codes were very repeatable with moderate-heavy acceleration prior to cleaning the MAF. The P0121 seemed more sporadic but just letting the engine idle in park for about 15 minutes would trigger it.

At idle the MAF reads between 6-8 g/s but read the same at idle before the cleaning. At the WOT run after the cleaning, the MAF is reading higher as seen in the VE calculations. My LTFT are now around 12-13% under heavy acceleration which still seems a tad high. So my questions are:

1. What is a reasonable VE for a stock L92 6.2L?

2. The MAF reading seems improved after cleaning, but is it still under-reporting based on the VE of ~72% I calculate?

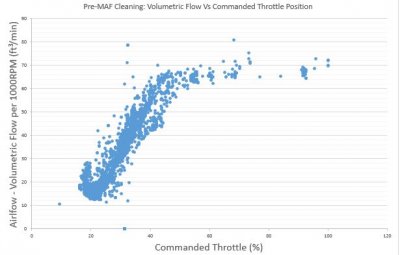

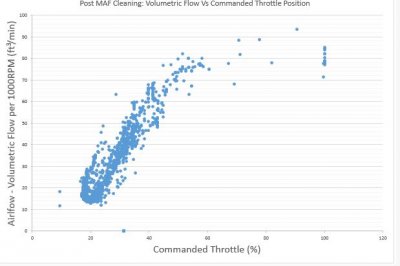

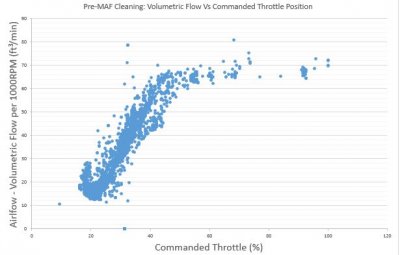

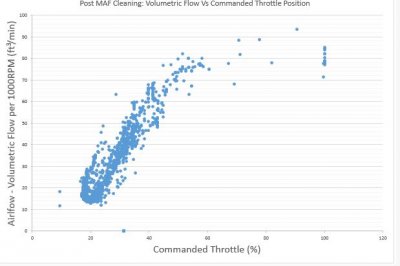

One other thing I found interesting... I figure the MAF reading is a combination of RPM and throttle opening. I took the volumetric airflow(cuft/min) calculations I got during the VE calculations and divided it by the engine rpm, then scaled that by 1000 to get a value that was easily readable and cross plotted that result with the commanded throttle actuator control. By looking at the plot, it seems the airflow per RPM increases linearly with commanded throttle then hits a wall at about 50% commanded throttle, after which you get no more airflow per RPM at larger throttle opening. Maybe I still have an issue or maybe that is how these are designed. After cleaning the MAF, the plotted values did increase.

So I've been dealing with a few error codes the past 2 months... P0121, P0171 and P0174 on my '07 Yukon Denali with 113k. Vehicle is completely stock besides a K&N air filter that I've had on for about 60k. There has been no engine work ever done. New plugs and wires at 100k. I've been logging OBDII data looking for a trend to point me in the right direction for a fix the past 2 weeks. The long term fuel trims max out at just over 24% under moderate to heavy acceleration but range about 0 to 5% at idle. MAP and MAF values appear normal(MAF is 6-8 g/s at idle) but I am not sure what they really should be. Commanded throttle and relative throttle position track each other nicely. Fuel pressure is 60 psi at idle, I haven't had a chance to check under heavy acceleration. I have taken my logged data during a few brief WOT runs and have calculated about 62% volumetric efficiency. I can't seem to find any info on what VE I should be expecting. To me, ~62% seems low?

This past weekend, I cleaned the MAF sensor and reran a WOT run today and now see about ~72% VE and my LFTF are about half of what they were before I cleaned the MAF and I haven't had any codes pop up over the last 3 days. The P0171 and P0174 lean codes were very repeatable with moderate-heavy acceleration prior to cleaning the MAF. The P0121 seemed more sporadic but just letting the engine idle in park for about 15 minutes would trigger it.

At idle the MAF reads between 6-8 g/s but read the same at idle before the cleaning. At the WOT run after the cleaning, the MAF is reading higher as seen in the VE calculations. My LTFT are now around 12-13% under heavy acceleration which still seems a tad high. So my questions are:

1. What is a reasonable VE for a stock L92 6.2L?

2. The MAF reading seems improved after cleaning, but is it still under-reporting based on the VE of ~72% I calculate?

One other thing I found interesting... I figure the MAF reading is a combination of RPM and throttle opening. I took the volumetric airflow(cuft/min) calculations I got during the VE calculations and divided it by the engine rpm, then scaled that by 1000 to get a value that was easily readable and cross plotted that result with the commanded throttle actuator control. By looking at the plot, it seems the airflow per RPM increases linearly with commanded throttle then hits a wall at about 50% commanded throttle, after which you get no more airflow per RPM at larger throttle opening. Maybe I still have an issue or maybe that is how these are designed. After cleaning the MAF, the plotted values did increase.