Got some rods in holes!

Ran out of plasti gauge near the end, hard stuff to keep track of once it falls out of the package.

but everything was coming out super consistent anyways.

I was able to check the two different batches of bearings, all very constant.

Crankshaft endplay came out to be .0025ish

I need to check camshaft endplay once i have the bolt torqued down, but the quick check i did looks good so far.

I also did some flow porting of the oil pump and minor polishing of the flow surfaces headed to the block and coming from the pan.

My camera didn't want to focus, and i was too lazy to go dig out the real camera.

But I used some tiny little 3m crossbuffs to blend and polish.

It looked pretty good, and i figured if i screwed up, then there is my excuse to replace the pump.

I also noticed that the pump housing to the crank timing gear fitment is VERY tight.

Like clearance the pump by the PITA method using lots of feeler gauges is unnecessary.

Just gut the pump and clearance the housing to the crank gear and it's centered perfectly!

This came about as I noticed that i had it slightly too tight on one side, scaring my gear and the pump housing a little...

And when disassembling the old 5.3, i got a little sloppy with the pump housing cover plate torx bits.

Stripping one, where i had to drill out the center in order to use an extractor.

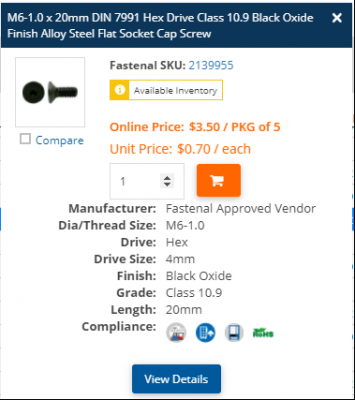

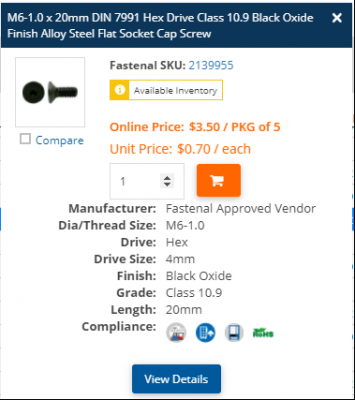

I contacted Melling to inquire about a replacement screw, they let me know they don't have any parts for sale but the did provide me the specs to the cover plate screws they use.

Well i went to the local hardware store, and i was able to find replacements no problem.

So I have a single screw that's an Allen socket, and the rest are torx.