I know there are a lot of posts published online about this, but I can’t find an answer to my specific question.

Yes, I am trying to learn what causes the lifter failure in the 5.3L and 6.2L V8 engines. I found something interesting about lifter failure in HEMI engines, and I wonder if the GM V8 engines experience the same type of failure.

The 5.7L and 6.4L HEMI V8 engines have an affinity for lifter failure like the GM engines do. No, I am not entirely sure it’s the same type of failure, but if it is, then I’m wanting to learn if there is a similar solution. Let me elaborate a bit more.

A master FCA technician spent years collaborating with an engineer to determine and find a solution for HEMI lifter failure. Hd referenced FCA’s lifter failure statistics, which found that most lifter failure events occurred in vehicles with high idle times and/or poor oil change maintenance. That led them into investigating oil lubrication quality at varying levels, such as at idle and throughout a range of throttle input.

Online, it seems the oldest and most popular theory among HEMI owners (and GM V8 owners) is that the cylinder deactivation technology (AFM, DFM, MDS) causes the problem. In the case of the HEMI engines, the technician emphasized that the same type of lifter failure occurred on both MDS and non-MDS V8 models, so he wasn’t convinced the cylinder deactivation is the root cause. It is still possible that MDS might have an effect in correlation with inadequate lubrication, but not the root cause, which is again according to the technician.

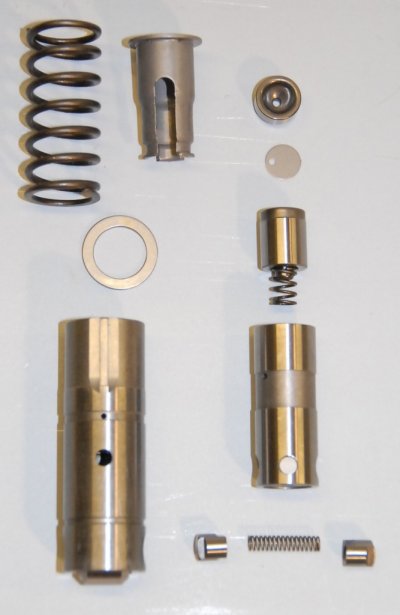

The technician and his engineer co-researcher concluded that inadequate oil lubrication at idle is the root cause of excessive lifter and camshaft wear, leading to premature failure. A ticking noise is a tale-tale sign of excessive lifter wear. His solution is to replace the stock oil pump with a higher volume oil pump, such as the Melling 10452HV oil pump. It increases the oil volume by 20%. According to the tech, it allows the oil to lubricate key areas that do not get properly oiled otherwise, thus preventing the excessive wear and tear.

Thoughts? Has anyone found information suggesting that inadequate lubrication is the root cause of lifter failure in the 5.3L and 6.2L V8 engines?

Yes, I am trying to learn what causes the lifter failure in the 5.3L and 6.2L V8 engines. I found something interesting about lifter failure in HEMI engines, and I wonder if the GM V8 engines experience the same type of failure.

The 5.7L and 6.4L HEMI V8 engines have an affinity for lifter failure like the GM engines do. No, I am not entirely sure it’s the same type of failure, but if it is, then I’m wanting to learn if there is a similar solution. Let me elaborate a bit more.

A master FCA technician spent years collaborating with an engineer to determine and find a solution for HEMI lifter failure. Hd referenced FCA’s lifter failure statistics, which found that most lifter failure events occurred in vehicles with high idle times and/or poor oil change maintenance. That led them into investigating oil lubrication quality at varying levels, such as at idle and throughout a range of throttle input.

Online, it seems the oldest and most popular theory among HEMI owners (and GM V8 owners) is that the cylinder deactivation technology (AFM, DFM, MDS) causes the problem. In the case of the HEMI engines, the technician emphasized that the same type of lifter failure occurred on both MDS and non-MDS V8 models, so he wasn’t convinced the cylinder deactivation is the root cause. It is still possible that MDS might have an effect in correlation with inadequate lubrication, but not the root cause, which is again according to the technician.

The technician and his engineer co-researcher concluded that inadequate oil lubrication at idle is the root cause of excessive lifter and camshaft wear, leading to premature failure. A ticking noise is a tale-tale sign of excessive lifter wear. His solution is to replace the stock oil pump with a higher volume oil pump, such as the Melling 10452HV oil pump. It increases the oil volume by 20%. According to the tech, it allows the oil to lubricate key areas that do not get properly oiled otherwise, thus preventing the excessive wear and tear.

Thoughts? Has anyone found information suggesting that inadequate lubrication is the root cause of lifter failure in the 5.3L and 6.2L V8 engines?