Dantheman1540

Full Access Member

"...What's in a part number? That which we call a 12634105, by any other number would spin as sweet?"

Answer: Purple

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

"...What's in a part number? That which we call a 12634105, by any other number would spin as sweet?"

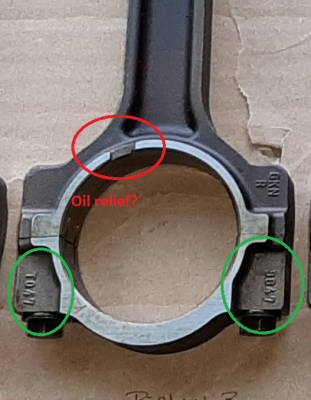

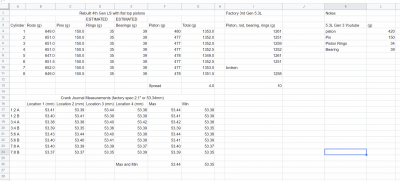

Years ago extrude honing was big. Not sure if they still do it.I'm on track to refurbish the parts, do some cleanup, and balancing. Worked for a long time on weighing the reciprocating mass (rods, pistons, etc). Chart with some figures thus far below.

Was amazed to see the factory rods spanned a weight range of 10 grams (granted they are not cleaned up). Gives and idea of tolerance on balancing.

I'm slowly but surely constructing a jig to measure the rod ends. Then I will remove material as necessary to balance the spread down to 1 gram or at least better than 4 grams.

Polishing Exhaust Runners

The LT1 I built, I ported matched and polished the heads both on intake and exhaust side. It was pretty crappy job where I simply cleaned up castings and widened to match the gaskets.

I'm going to leave the intake side alone on these 317 heads but started working on polishing the exhaust ports. I'm not going to bother matching them via the gaskets either. I may cc the cylinder side though, that looks pretty simple.

However, I need to know how to really polish, get a mirror finish, on the exhaust ports. I'm currently VERY slowly removing sand casting finish with a 120 grit Dremel wheels. I need some sort of rubbing compound after that to clean up the grove the sanding wheel put in it. Any ideas?

View attachment 265602 View attachment 265606