Monkey_Wrench

TYF Newbie

- Joined

- Sep 15, 2021

- Posts

- 19

- Reaction score

- 16

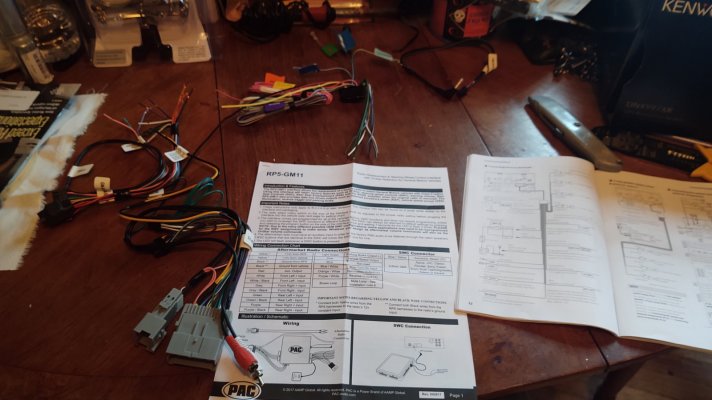

I'm working on beefing up the sound system in my '05 Escalade. I'm not looking for building leveling power. Just want to clean up the sound, fill it out more where it's missing some depth, and add some extra functionality.

To begin with I have installed Newish Old Stock headrest monitors (one was new, the other had a used "brain" but the monitor was "only used for testing purposes. More on that later)

First step was getting the original headrests out. This side came out ok with a paperclip, I needed to use a sturdier tool to get the other side to cooperate. Note the wire that I used. It isn't the monitor wire. That is soft and floppy. I ran a stiffer wire with semi flexible insulation to find find the path through first. You could also use electrician's "fish tape" which is a semi stiff wire on a retractable spool that you push through then attach you wire you want to run to it and pull it back through.

The next bit of a faff was getting the bottom of the seat back to unhook from itself. Was a bit fiddly bit did come free with some brute force applied.

Simple enough. Still has the protective film from the factory on it.

Another view of the other side seat back bottom. Both sides have a bit of a wedge to latch to each other. After the ease of the first one I was apparently arrogant and the Gods of installion were displeased. The headrest on this side took almost an hour of messing with trying to use the paperclip to get it out before I went to get a different pointy tool, and the bottom took a good half hour of hand cramping frustration to get apart.

After giving up on finesse I reverted back to force and once one end bent enough to let loose it came undone like a zipper. Getting it back together was a snap at least.

To begin with I have installed Newish Old Stock headrest monitors (one was new, the other had a used "brain" but the monitor was "only used for testing purposes. More on that later)

First step was getting the original headrests out. This side came out ok with a paperclip, I needed to use a sturdier tool to get the other side to cooperate. Note the wire that I used. It isn't the monitor wire. That is soft and floppy. I ran a stiffer wire with semi flexible insulation to find find the path through first. You could also use electrician's "fish tape" which is a semi stiff wire on a retractable spool that you push through then attach you wire you want to run to it and pull it back through.

The next bit of a faff was getting the bottom of the seat back to unhook from itself. Was a bit fiddly bit did come free with some brute force applied.

Simple enough. Still has the protective film from the factory on it.

Another view of the other side seat back bottom. Both sides have a bit of a wedge to latch to each other. After the ease of the first one I was apparently arrogant and the Gods of installion were displeased. The headrest on this side took almost an hour of messing with trying to use the paperclip to get it out before I went to get a different pointy tool, and the bottom took a good half hour of hand cramping frustration to get apart.

After giving up on finesse I reverted back to force and once one end bent enough to let loose it came undone like a zipper. Getting it back together was a snap at least.