strutaeng

Full Access Member

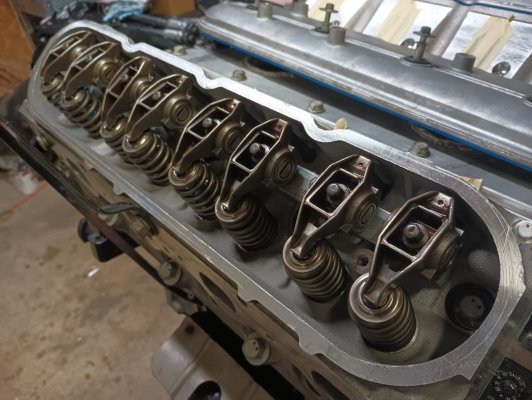

What?!I've have also used oem bolts and tighten the bolts as if they were arp bolts and have one to fail yet.

I was thinking of "Hooks Law stress-strain equation" as I was yielding the bolts on the last 2 passes: the force kinda seems to vary to keep the rotation going to keep the angle going at a constant rate.... Kinda hard to explain... certainly takes some grunt to do that, LoL. I'm glad I had lunch prior to doing that.