Fless,

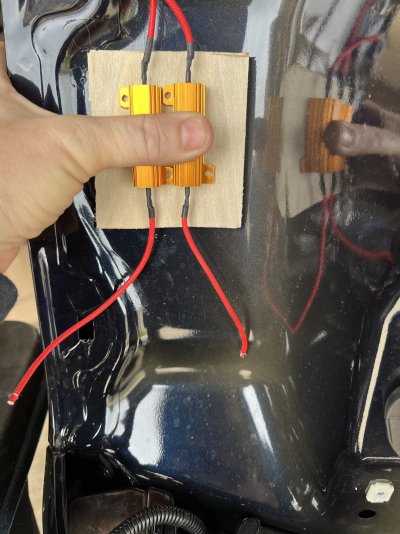

You are nt the only one to consider the heat sink angle. U had them in there for seven months with no issues. The other thought although not verified by electrical engineers with certified calibrated test equipment…..Electro Magnetic Interference (EMI).

After the installation I had no hyper flash, no CANBUS errors, perfectly timed and sequenced turn brake and back up light application. The model bulb I used was ALLA 7440/7443/T921 bulbs. Brake and Reverse lights were a three flash then solid bulbs. Turn signals were Amber LED but didnt have to worry about the three flash first.

With almost a year of the LED upgrade spread across two different vehicles I only had the CANBUS Error. The typical Resistor heated up during extended traffic delays. The CANBUS error was turn signal related. After the turn was made and resistor cooled off no further issues.

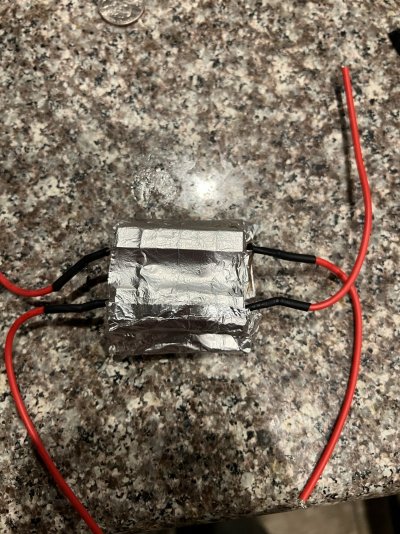

I admit I might have gone a bit overkill on the Aluminum foil but think about this. If the bulbs are installed correctly, resistors are wired correctly and mounting plate is oriented correctly….…..The lens and bulbs should never have to be removed again. This area for the most part is not a common inspection item. Unless the lens assembly is removed for some other reason then this is a set and forget item.

If the lens assembly does have to be removed for whatever reason, then probably a good as time as any to check the areas for melting, (plastic lens assembly, wiring etc…)