You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NHTSA opens preliminary probe into more than 870,000 GM vehicles

- Thread starter cjlewis

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Vladimir2306

Full Access Member

- Joined

- May 18, 2023

- Posts

- 547

- Reaction score

- 532

Reading all this.. if clearances are a problem on pistons… it seems to me that a 207 deg was what 2018 l83 had… is that still what it is on the 2024s? I know you get down south.. the gm cooling is weak..

Cooling is good; on the 5th generation the engine runs at a lower temperature. If K2 worked at 100C, then T1 already at 90C

Vladimir2306

Full Access Member

- Joined

- May 18, 2023

- Posts

- 547

- Reaction score

- 532

It seems to me that the video perfectly confirms my version about small gaps. 4 miles, Oil pump ok, crankshaft ok. The piston seat fell apart because it was difficult for it to move in the cylinder

The failure mechanism was not oil related or clearance related on this specific engine. It appears that the wrist pin C clip was either missing or installed incorrectly, or the piston C clip groove was not machined in the wrist pin hole, so this would likely be considered manufacturing or an assembly problem. This piston was in the rear of the engine, so likely cylinder #7 or #8. The missing clip allowed the piston wrist pin to walk sideways and then the piston became bound or cocked in the cylinder and caused the piston to become bound in the cylinder. Then the weak link in the chain was the connecting rod which broke. I believe these connecting rods are not forged steel but compressed sintered iron.

This is the style of the piston wrist pin retaining clip, seems to be the same design GM has used for years but IMHO not an ideal style based upon what I have dealt with over the years in high performance applications:

What is a bit surprising is that GM did not want this 4 mile engine returned for failure analysis. As the shop that received the engine noted the oil pan was already off so it was unclear if the piston wrist pin C clip fell out or was actually missing. Based on the style of wrist pin C clips, they are not what I would call severe duty or high performance. They just appear to be round wire curved clips.

This may have been a small percentage assembly failure or it may have been a more common failure.

Here is another good video that allows you to see what a higher mileage failure looks like. In this engine it appears the #1 rod bearing failed or spun that likely led to the catastrophic failure. But in any event it allows forum members to see what is inside these engines.

This is the style of the piston wrist pin retaining clip, seems to be the same design GM has used for years but IMHO not an ideal style based upon what I have dealt with over the years in high performance applications:

What is a bit surprising is that GM did not want this 4 mile engine returned for failure analysis. As the shop that received the engine noted the oil pan was already off so it was unclear if the piston wrist pin C clip fell out or was actually missing. Based on the style of wrist pin C clips, they are not what I would call severe duty or high performance. They just appear to be round wire curved clips.

This may have been a small percentage assembly failure or it may have been a more common failure.

Here is another good video that allows you to see what a higher mileage failure looks like. In this engine it appears the #1 rod bearing failed or spun that likely led to the catastrophic failure. But in any event it allows forum members to see what is inside these engines.

Last edited:

Vladimir2306

Full Access Member

- Joined

- May 18, 2023

- Posts

- 547

- Reaction score

- 532

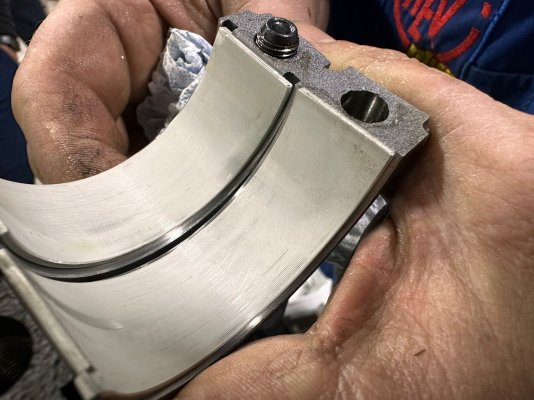

Look, this is a photo of a new engine that just arrived for service the other day. Engine out of the box, mileage 0 km. There are already scratches on the cylinder mirror and marks on the liners.The failure mechanism was not oil related or clearance related on this specific engine. It appears that the wrist pin C clip was either missing or installed incorrectly, or the piston C clip groove was not machined in the wrist pin hole, so this would likely be considered manufacturing or an assembly problem. This piston was in the rear of the engine, so likely cylinder #7 or #8. The missing clip allowed the piston wrist pin to walk sideways and then the piston became bound or cocked in the cylinder and caused the piston to become bound in the cylinder. Then the weak link in the chain was the connecting rod which broke. I believe these connecting rods are not forged steel but compressed sintered iron.

This is the style of the piston wrist pin retaining clip, not an ideal style based upon what I have dealt with over the years:

What is a bit surprising is that GM did not want this 4 mile engine returned for failure analysis. As the shop that received the engine noted the oil pan was already off so it was unclear if the piston wrist pin C clip fell out or was actually missing. Based on the style of wrist pin C clips, they are not what I would call severe duty or high performance. They just appear to be round wire curved clips.

This may have been a small percentage assembly failure or it may have been a more common failure.

Here is another good video that allows you to see what a higher mileage failure looks like. In this engine it appears the #1 rod bearing failed or spun that likely led to the catastrophic failure. But in any event it allows forum members to see what is inside these engines.

Attachments

-

84fca3c8-f0cd-4e5e-8c7d-3bff112cc91c (1).jpg269.7 KB · Views: 9

84fca3c8-f0cd-4e5e-8c7d-3bff112cc91c (1).jpg269.7 KB · Views: 9 -

25be7715-7f22-487c-ab16-5d4f1c6e9cfc (1).jpg296.7 KB · Views: 9

25be7715-7f22-487c-ab16-5d4f1c6e9cfc (1).jpg296.7 KB · Views: 9 -

b58b6025-8605-47fa-9b49-0a3a45c0f061 (1).jpg202.2 KB · Views: 9

b58b6025-8605-47fa-9b49-0a3a45c0f061 (1).jpg202.2 KB · Views: 9 -

c0153bc6-ebe7-47a5-8cbb-365ba24183e1.jpg177.6 KB · Views: 9

c0153bc6-ebe7-47a5-8cbb-365ba24183e1.jpg177.6 KB · Views: 9 -

c018c64d-340c-4866-898c-2f1a77ad1f5d.jpg266.4 KB · Views: 9

c018c64d-340c-4866-898c-2f1a77ad1f5d.jpg266.4 KB · Views: 9

You clearly have pictures of a new engine. While I am not there to personally inspect and "feel" the finish, what I am seeing is not significantly concerning. Could things look better, sure they could.

So understand at the engine assembly plant they "Cold Test" newly build engines by spinning them with a large electric motor and they measure intake and exhaust airflow as well as the torque required to turn the engine with the electric motor to determine if the build is within the spec range they expect.

I assume this "Cold Test" is performed with oil in the crankcase, but it is unclear if the oil system is pre-primed or if the "Cold Test" starts at a slower RMP to build oil pressure then to increase RPM after a specific number of engine revolutions. No idea if the oil is pre-warmed before the engine is filled with oil, I hope is would be.

Seems that there is something either with the initial build on these engines or something with parts that may be causing problems. I would be interested to know if your shop actually checks the original build bearing clearances with Plastigauge to figure out if the engines bearings are too tight or too loose.

So understand at the engine assembly plant they "Cold Test" newly build engines by spinning them with a large electric motor and they measure intake and exhaust airflow as well as the torque required to turn the engine with the electric motor to determine if the build is within the spec range they expect.

I assume this "Cold Test" is performed with oil in the crankcase, but it is unclear if the oil system is pre-primed or if the "Cold Test" starts at a slower RMP to build oil pressure then to increase RPM after a specific number of engine revolutions. No idea if the oil is pre-warmed before the engine is filled with oil, I hope is would be.

Seems that there is something either with the initial build on these engines or something with parts that may be causing problems. I would be interested to know if your shop actually checks the original build bearing clearances with Plastigauge to figure out if the engines bearings are too tight or too loose.

Vladimir2306

Full Access Member

- Joined

- May 18, 2023

- Posts

- 547

- Reaction score

- 532

The fact of the matter is that our service disassembles a completely new engine from the box, grinds out the gaps, checks all the tightness and reassembles the engine)))You clearly have pictures of a new engine. While I am not there to personally inspect and "feel" the finish, what I am seeing is not significantly concerning. Could things look better, sure they could.

So understand at the engine assembly plant they "Cold Test" newly build engines by spinning them with a large electric motor and they measure intake and exhaust airflow as well as the torque required to turn the engine with the electric motor to determine if the build is within the spec range they expect.

I assume this "Cold Test" is performed with oil in the crankcase, but it is unclear if the oil system is pre-primed or if the "Cold Test" starts at a slower RMP to build oil pressure then to increase RPM after a specific number of engine revolutions. No idea if the oil is pre-warmed before the engine is filled with oil, I hope is would be.

Seems that there is something either with the initial build on these engines or something with parts that may be causing problems. I would be interested to know if your shop actually checks the original build bearing clearances with Plastigauge to figure out if the engines bearings are too tight or too loose.

Much quicker and easier to go thru the motor when fresh and out of the vehicle.

It would be interesting if this problem is really a production issue or an oil starvation issue due to the oil viscostity, level and pressure?

I think at this point the root cause of the problem is not 100% apparent as we may not have seen many of the early engine failures opened up and displayed. I assume and hope GM knows what is going on and has identified and resolved the problems.

You should have your guys track the build dates on the engines to see if they find changes and improvements.

The build date is a Julian date on a paper tag on the rear of the drivers side cylinder head as least for engines installed in vehicles. Not 100% the replacement engines have these same or similar tags?

See this attached picture, the build date is after the N1 on the bottom row. The tag on this motor indicates is as build in on the 56th day of 2021. 21=2021, 056=56th day of the year.

It would be interesting if this problem is really a production issue or an oil starvation issue due to the oil viscostity, level and pressure?

I think at this point the root cause of the problem is not 100% apparent as we may not have seen many of the early engine failures opened up and displayed. I assume and hope GM knows what is going on and has identified and resolved the problems.

You should have your guys track the build dates on the engines to see if they find changes and improvements.

The build date is a Julian date on a paper tag on the rear of the drivers side cylinder head as least for engines installed in vehicles. Not 100% the replacement engines have these same or similar tags?

See this attached picture, the build date is after the N1 on the bottom row. The tag on this motor indicates is as build in on the 56th day of 2021. 21=2021, 056=56th day of the year.

Interesting YouTube video, while this is a 2017 6.2l with over 100k miles, the engine is VERY clean and it appears only 1 bearing had any issues. The main bearing cap was not removed in the video and it is unclear if any of the cam bearings started to flake or fail. From the metal in the oil pan, it looks like more than just from the one rod bearing.

If I was rebuilding or reworking new engines, I would likely go with King Engine Bearings. Even if buying a new motor, I would likely at least replace the main and rod bearings.

I wonder if the same style of bearings were used in the 1999-2006 6.0l engines. I have one that is over 275k miles and still going without lifter or bearing issues.

If I was rebuilding or reworking new engines, I would likely go with King Engine Bearings. Even if buying a new motor, I would likely at least replace the main and rod bearings.

I wonder if the same style of bearings were used in the 1999-2006 6.0l engines. I have one that is over 275k miles and still going without lifter or bearing issues.

blanchard7684

Senior Member

- Joined

- Dec 23, 2024

- Posts

- 148

- Reaction score

- 44

That is a gnarly looking bearing. Doesn’t look like debris or oil starvation. That actually looks like a defect bearing delaminatingInteresting YouTube video, while this is a 2017 6.2l with over 100k miles, the engine is VERY clean and it appears only 1 bearing had any issues. The main bearing cap was not removed in the video and it is unclear if any of the cam bearings started to flake or fail. From the metal in the oil pan, it looks like more than just from the one rod bearing.

If I was rebuilding or reworking new engines, I would likely go with King Engine Bearings. Even if buying a new motor, I would likely at least replace the main and rod bearings.

I wonder if the same style of bearings were used in the 1999-2006 6.0l engines. I have one that is over 275k miles and still going without lifter or bearing issues.

Similar threads

- Locked

- Replies

- 61

- Views

- 9K

- Replies

- 11

- Views

- 913

- Replies

- 9

- Views

- 1K

- Replies

- 22

- Views

- 8K

- Replies

- 14

- Views

- 4K