YukonLover

TYF Newbie

- Joined

- Nov 20, 2024

- Posts

- 3

- Reaction score

- 0

Hello everyone

I have a 2001 yukon XL 1500 2wd slt. Had ujoints go on me. Took the shaft out to replace. Easy to get out. Nightmare to replace joints.

My 2003 slt xl 1500 4wd is all steel shafts. I was confused to see an aluminum shaft on a 5600lb truck. Insane. They used to be expensive to manufacture lightweight aluminum for racing that you'd throw away when they go bc aluminum can't hold uo as well as steel. Now it's in this type of application... nutz!

My biggest issue is that I can't get the joint out. It teeters on the edge with one cap released. Its like .01 cm from being free, but can't. It gouged the smooth machine finish where is sits as well. I'm worried about all of this. The aluminum is trying to mate to the steel cap and I'm assuming the aluminum has to be torched first for this to work.

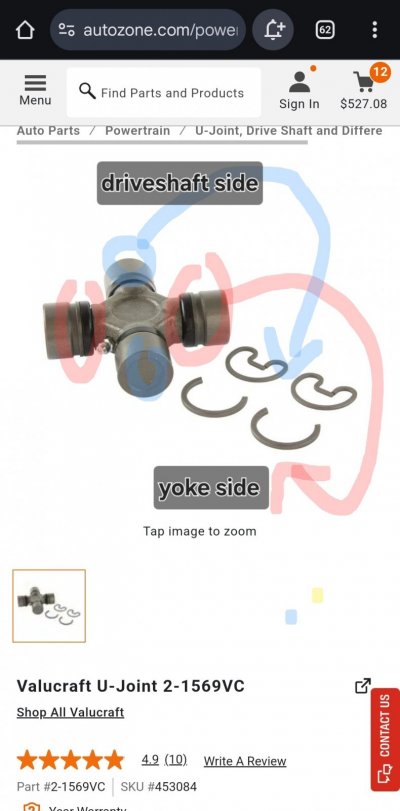

I went with these valucraft 2-4800 VC. Computer at the store alleged a fit. Now when I looked up the same model on the site it says for aluminum driveshafts use 2-4801DL part number doesn't exist. Moog makes some, 354 and 355, says steel and aluminum, but not the right clips. I was just gonna take it to a shop and have them press them out clean, file and install tomorrow. I'm on a time crunch, it's my only car at the moment. Will I be ok with the valucraft 2-4800VC? What do you guys think?

Also, the aluminum shaft is considerably larger diameter and the tube is flared by the end caps.. the flared end gives it am inflated value. You cant get a small 7/16 shallow socket on there. I used a wrench and oil to get the bolts off for rhe shackles. I don't see how I can torque these down. Any tricks?

Thank you!

I have a 2001 yukon XL 1500 2wd slt. Had ujoints go on me. Took the shaft out to replace. Easy to get out. Nightmare to replace joints.

My 2003 slt xl 1500 4wd is all steel shafts. I was confused to see an aluminum shaft on a 5600lb truck. Insane. They used to be expensive to manufacture lightweight aluminum for racing that you'd throw away when they go bc aluminum can't hold uo as well as steel. Now it's in this type of application... nutz!

My biggest issue is that I can't get the joint out. It teeters on the edge with one cap released. Its like .01 cm from being free, but can't. It gouged the smooth machine finish where is sits as well. I'm worried about all of this. The aluminum is trying to mate to the steel cap and I'm assuming the aluminum has to be torched first for this to work.

I went with these valucraft 2-4800 VC. Computer at the store alleged a fit. Now when I looked up the same model on the site it says for aluminum driveshafts use 2-4801DL part number doesn't exist. Moog makes some, 354 and 355, says steel and aluminum, but not the right clips. I was just gonna take it to a shop and have them press them out clean, file and install tomorrow. I'm on a time crunch, it's my only car at the moment. Will I be ok with the valucraft 2-4800VC? What do you guys think?

Also, the aluminum shaft is considerably larger diameter and the tube is flared by the end caps.. the flared end gives it am inflated value. You cant get a small 7/16 shallow socket on there. I used a wrench and oil to get the bolts off for rhe shackles. I don't see how I can torque these down. Any tricks?

Thank you!

Attachments

Last edited: