skpyle

Full Access Member

- Joined

- May 15, 2021

- Posts

- 420

- Reaction score

- 1,106

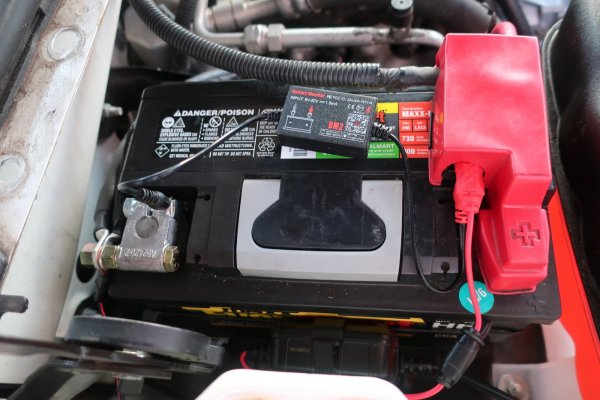

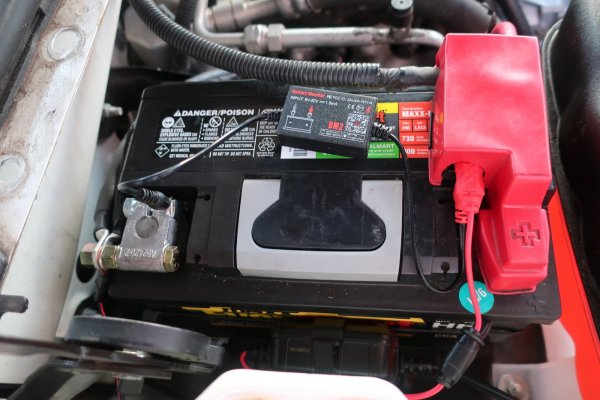

I installed a NOCO Genius 2D onboard battery maintainer. Actually, I used two large zip ties to secure the mount to the side of the battery. I could not find a place to mount the unit near the battery that I was happy with. Side of the battery is not ideal, but it will work. Even though my Escalade is my daily driver, I like having a maintainer installed. Just in case. All 4 of the vehicles at my house have the NOCO Genius 2Ds installed.

Not the most elegant install, but it works.

Location of battery maintainer on the side of the battery means I can't see the indicator to see if it is charging. However, I can look at the battery monitor app on my phone and see the voltage.

I also installed a QUICKLYNKS BM2 Battery Monitor II bluetooth battery monitor. Same as above, I have one on all my vehicles. Just because. I mounted this one on top of the battery, and will secure it with a zip tie to the (+) power feed cable once all is said and done.

Battery monitor will live on top of the battery.

Both the battery maintainer and monitor (+) terminals have been connected to the battery side of the mega fuse at the (+) battery cable terminal.

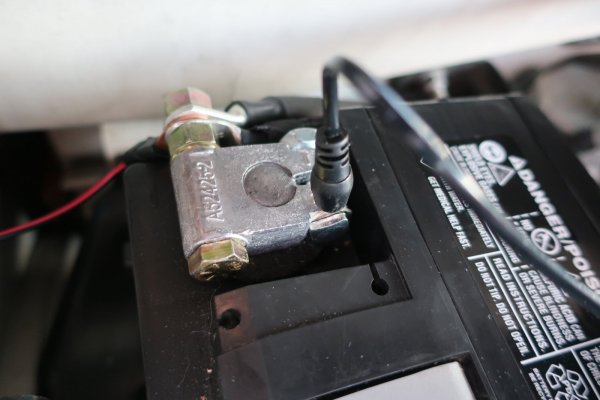

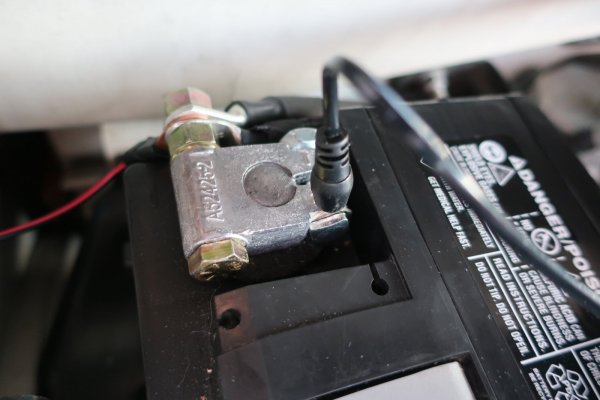

New (-) battery terminal. Not as elegant as I had wanted, but it is solid and functional.

Not the most elegant install, but it works.

Location of battery maintainer on the side of the battery means I can't see the indicator to see if it is charging. However, I can look at the battery monitor app on my phone and see the voltage.

I also installed a QUICKLYNKS BM2 Battery Monitor II bluetooth battery monitor. Same as above, I have one on all my vehicles. Just because. I mounted this one on top of the battery, and will secure it with a zip tie to the (+) power feed cable once all is said and done.

Battery monitor will live on top of the battery.

Both the battery maintainer and monitor (+) terminals have been connected to the battery side of the mega fuse at the (+) battery cable terminal.

New (-) battery terminal. Not as elegant as I had wanted, but it is solid and functional.

Last edited: