davidavidd

Member

Hi TYF members and friends! I appreciate all your opinions and replies to find the origin of this situation

To make a long story short:

My transmission was working fine until this week. I rebuilt it with your help two years and 65.000 miles ago when the pump went bad.

I drove the Tahoe on a small family trip (perfect road in Colombia, nice wheather, 120 miles, 5 people). Already in place when trying to park I discovered that the reverse gear did not have enough force to move the truck, it moves but very little, five seconds later it started to sound like metal parts rubbing against each other (I thought it was the diff dying), turned off the engine and when I put it back in reverse it simply didn't move anymore (reverse = neutral).

The only strange thing I noticed this day (one hour before failing) was a lack of acceleration and force in first gear (like limp mode until finally reach the 2nd gear).

Since I couldn't spend the night at the site I decided to take the risk and drive back home. No reverse but the truck worked fine in forward gears.

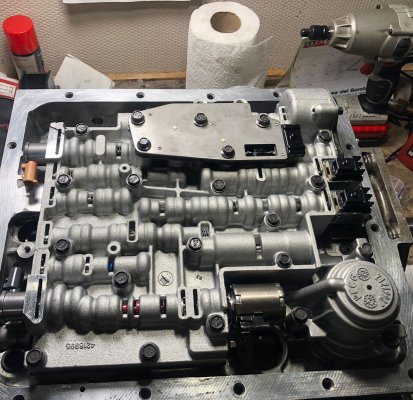

This weekend I was expecting to find a carnage with my sun gear on pieces or the sun shield without teeths but that was not the case. Other than some endplay between parts and contaminated oil (with clutch and steels particles), the only visible damage was the low/reverse frictions and steels (pistons ok, check balls ok, valve body gasket ok, sprags ok). Please see the photos, the low/reverse clutch pack and steels looks like charcoal.

Technical summary

2007 Tahoe, stock Engine 5.3, RWD, 275/55/R20

Street use only/not towing.

Oil was at normal level at time of failure (I checked before leaving in the morning).

The transmission filter and the neodymium magnet in the pan were full of particles and debris from clutch discs and steels.

Pressure measured in transmission before disassembly: 85PSI at idle and 120 in R.

After opening the torque converter I only found normal dirt for this type of damage. Bearings and inner clutch in OK condition.

In the first repair of this transmission I changed: sunshell (but not sun gear) frictions, internal parts of the pump, pistons, corvette servo, checkballs and everything included in a rebuild kit: seals, gaskets, bushings, bearings, sprags, etc. plus a transgo shift kit (the basic one). The hard parts/case/converter was reused.

Codes found w/ my scanner:

P0741: Torque Converter Clutch Circuit Performance or Stuck Off

P0745: Pressure Control Solenoid Malfunction

PD: I thought a lot about the engineer's mom who decided to put the Torx-50 sh** in the transmission bell (it took me 4 hours, sweat, pain and all kind of tools to remove a bolt with stripped head). These bolts won't come back, I'm going to replace them with low-profile bolts.

To make a long story short:

My transmission was working fine until this week. I rebuilt it with your help two years and 65.000 miles ago when the pump went bad.

I drove the Tahoe on a small family trip (perfect road in Colombia, nice wheather, 120 miles, 5 people). Already in place when trying to park I discovered that the reverse gear did not have enough force to move the truck, it moves but very little, five seconds later it started to sound like metal parts rubbing against each other (I thought it was the diff dying), turned off the engine and when I put it back in reverse it simply didn't move anymore (reverse = neutral).

The only strange thing I noticed this day (one hour before failing) was a lack of acceleration and force in first gear (like limp mode until finally reach the 2nd gear).

Since I couldn't spend the night at the site I decided to take the risk and drive back home. No reverse but the truck worked fine in forward gears.

This weekend I was expecting to find a carnage with my sun gear on pieces or the sun shield without teeths but that was not the case. Other than some endplay between parts and contaminated oil (with clutch and steels particles), the only visible damage was the low/reverse frictions and steels (pistons ok, check balls ok, valve body gasket ok, sprags ok). Please see the photos, the low/reverse clutch pack and steels looks like charcoal.

Technical summary

2007 Tahoe, stock Engine 5.3, RWD, 275/55/R20

Street use only/not towing.

Oil was at normal level at time of failure (I checked before leaving in the morning).

The transmission filter and the neodymium magnet in the pan were full of particles and debris from clutch discs and steels.

Pressure measured in transmission before disassembly: 85PSI at idle and 120 in R.

After opening the torque converter I only found normal dirt for this type of damage. Bearings and inner clutch in OK condition.

In the first repair of this transmission I changed: sunshell (but not sun gear) frictions, internal parts of the pump, pistons, corvette servo, checkballs and everything included in a rebuild kit: seals, gaskets, bushings, bearings, sprags, etc. plus a transgo shift kit (the basic one). The hard parts/case/converter was reused.

Codes found w/ my scanner:

P0741: Torque Converter Clutch Circuit Performance or Stuck Off

P0745: Pressure Control Solenoid Malfunction

PD: I thought a lot about the engineer's mom who decided to put the Torx-50 sh** in the transmission bell (it took me 4 hours, sweat, pain and all kind of tools to remove a bolt with stripped head). These bolts won't come back, I'm going to replace them with low-profile bolts.