There is nothing in the description about compression stroke, because you are automatically in the compression stroke, when the two marks are in line with each other, i.e. the crankshaft is at 12 o'clock and the camshaft is at 6 o'clock.

And that's all you need to know.

It's also right, that it's best to do this in this position and that only for one reason:

Because you see if your timing is correct.

It's of course also right that you can change the timing chain at any position, if you put it back on without moving crank and camshaft but may be, the camshaft twists a bit, due to the tension of the valve springs and you then no longer know which tooth is exactly the right point.

So it is best to turn the engine to the appropriate marks to take the timing chain down and reassemble the timing chain back on and then crank the engine once, which means you have to turn the crankshaft twice.

Then the marks are back in the right place and must match. Manual cranking also prevents mechanical damage generated if the timing chain is not placed correctly, because you notice when the piston hits the valves without making damage.

When you do that with the starter, you notice it as well. But then you have to check the manual for the section engine swap.

That's why you should crank the engine twice by hand. Two crankshaft rotation, check. Two rotations again, check again.

If the markings are still correct, then everything is fine and you can reassemble the engine.

At the LS engines that is as simple as it can be. If you see some German engines from BMW or Porsche.

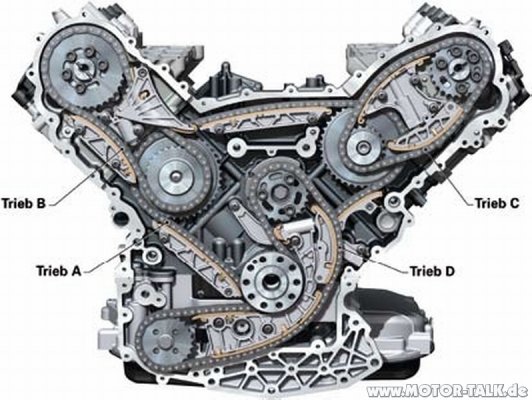

In a V8 with 4 camshafts, they sometimes have several balancing shafts and a high-pressure injection pump that has to be also lined, plus a chain tensioner. Then it becomes really difficult and usually only to do with setting tools.

I never in my mechanic life, saw a timing chain which is so simple like on the LS...