Don't take this personal, but your soldering needs some help. I wouldn't leave it like that. You can't get a shrink tube over it, and that looks horrible.

It looks like you tried the, "spread the strands, and intermingle" method. I would heat that back up and separate it and try again, or cut it off.

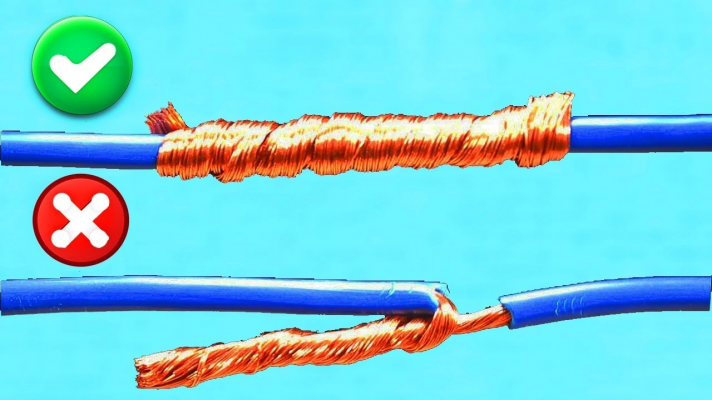

Tried to find a pic of what I think is the best way. If you cut lets say an inch off the end on both, then you overlap by a little more than half, make an X, and then twist together tight like the top. Then you can heat and add solder over top. (So even though you cut 1/2 off, and you don't completely overlap, it only ends up being about 3/4" exposed).

View attachment 411546

I've found unless I'm doing stuff on boards, I rarely even like soldering anymore, and only stuff that's between 12 and 16awg. Anything outside of that, I think a PROPER crimper does a better job. It's quicker, cleaner, and just as secure.

For smaller stuff, and hard to reach areas, if I really want a soldered connection, I use these self-solder shrink tubes: