Alex_M

Full Access Member

- Joined

- Sep 27, 2021

- Posts

- 376

- Reaction score

- 678

Later than intended, but here we are. This guide is for '99-'02 only - there are some differences in the swap for '03-'07 trucks.

Parts you will need are as follows:

-TBSS or '07-'14 Intake Manifold, obviously. Make sure you get a cathedral port intake manifold, not a square port intake off of a 2500 or 3500 truck.

-'07-'14 Fuel Rails

-'07-'14 Purge Valve - Some fuel rails include this

-C5 Corvette Fuel Filter - this is the return style fuel filter which will allow you to use the later model fuel rails with your existing fuel system.

-3 ft 5/16 Rubber Fuel Line - Low pressure line is fine, this is for emissions equipment.

-4 Hose Clamps

-3 Bolt to 4 Bolt Throttle Body Adapter -OR- 92mm fly-by-cable throttle body

-I recommend new intake gaskets, though they are not strictly required.

-This could also be a good time to do knock sensors and knock sensor harness, though also not strictly required.

Note: 92mm throttle body may require changing your intake tube. I did not try the stock tube, I upgraded my intake tube at the same time. I personally like to get the eBay "cold air" intake kit and retain the factory filter box. Most of these parts I sourced through eBay, with the exception of the fuel line, hose clamps, and intake gaskets which I sourced locally. I did first get a set of eBay intake gaskets as well, but they were molded incorrectly and were unusable.

I did not take pictures all the way through the process, but here are pictures showing mine as assembled with notes to let you know exactly what you need to know.

From this image you can see the throttle body and general assembly. This also gives you a good view of how I decided to route the breather hose from the valve cover to the throttle body. This is one of the locations you will use some of the 5/16 fuel line. This hose does not need hose clamps, the hose is a nice tight fit as is. I squirt a little oil in the hose ends before sliding onto the barb connections for easy assembly.

Here you can see where I moved the MAP sensor forward on the intake manifold. There is enough wire length in the factory wiring harness that no cutting or extending is required. It does not engage any kind of physical lock to secure it in place, but it is never under pressure and so does not need to be locked in - the silicon seal on the sensor is plenty to secure it in place.

Here you can see I did a kind of shoddy job trimming the hold down for the wiring harness so it could be secured by a nut. You could do a tidier job, but I was in a hurry to get my work truck back up and running so little effort went into the aesthetics by this point.

One of the factory bolts that are to mount the later model engine cover in place is in the correct location to mount the throttle cable bracket. This is the one shoddy part of this project - there is no further way to secure the bracket to the intake without either adding pieces of fabricating a bracket extension that would extend to another bolt. I have had no issues out of this setup so far, but I am very tempted by the prospect of modelling and 3d printing a piece that would fit around the ridges on the intake, glued into place, that could then further secure the bracket to prevent any rotation. That said - 2500 miles so far, so far so good.

Another shot of the same. I personally did not retain the EGR system, though there is an allocation in the TBSS intake that you could retain it if you wished to. You can always make a plate to block off the connection from the exhaust manifold to the hot side EGR tube to disable the system, leaving the valve in place to prevent a code from being thrown. Alternatively, you could dremel out the opening in the intake and get a brass fitting to heat and insert into the bolt hole provision in the intake and fully retain the system. In fact, you could likely heat and remove the threaded brass fitting from your factory intake to then insert it back into the TBSS intake. For myself, I deleted all of it and installed shorty headers which had no EGR provision to begin with.

Parts you will need are as follows:

-TBSS or '07-'14 Intake Manifold, obviously. Make sure you get a cathedral port intake manifold, not a square port intake off of a 2500 or 3500 truck.

-'07-'14 Fuel Rails

-'07-'14 Purge Valve - Some fuel rails include this

-C5 Corvette Fuel Filter - this is the return style fuel filter which will allow you to use the later model fuel rails with your existing fuel system.

-3 ft 5/16 Rubber Fuel Line - Low pressure line is fine, this is for emissions equipment.

-4 Hose Clamps

-3 Bolt to 4 Bolt Throttle Body Adapter -OR- 92mm fly-by-cable throttle body

-I recommend new intake gaskets, though they are not strictly required.

-This could also be a good time to do knock sensors and knock sensor harness, though also not strictly required.

Note: 92mm throttle body may require changing your intake tube. I did not try the stock tube, I upgraded my intake tube at the same time. I personally like to get the eBay "cold air" intake kit and retain the factory filter box. Most of these parts I sourced through eBay, with the exception of the fuel line, hose clamps, and intake gaskets which I sourced locally. I did first get a set of eBay intake gaskets as well, but they were molded incorrectly and were unusable.

I did not take pictures all the way through the process, but here are pictures showing mine as assembled with notes to let you know exactly what you need to know.

From this image you can see the throttle body and general assembly. This also gives you a good view of how I decided to route the breather hose from the valve cover to the throttle body. This is one of the locations you will use some of the 5/16 fuel line. This hose does not need hose clamps, the hose is a nice tight fit as is. I squirt a little oil in the hose ends before sliding onto the barb connections for easy assembly.

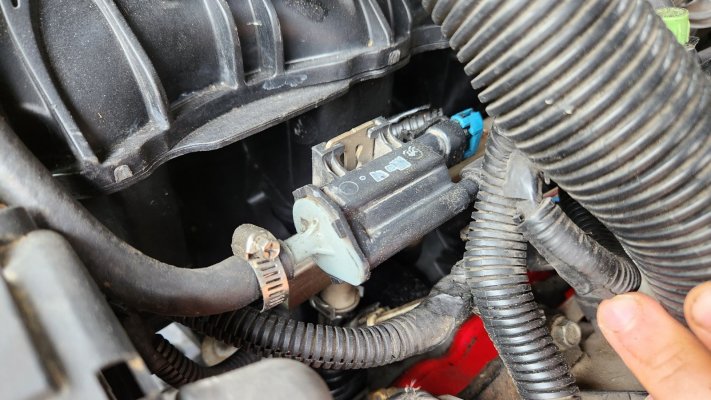

Here you can see where I moved the MAP sensor forward on the intake manifold. There is enough wire length in the factory wiring harness that no cutting or extending is required. It does not engage any kind of physical lock to secure it in place, but it is never under pressure and so does not need to be locked in - the silicon seal on the sensor is plenty to secure it in place.

Here you can see I did a kind of shoddy job trimming the hold down for the wiring harness so it could be secured by a nut. You could do a tidier job, but I was in a hurry to get my work truck back up and running so little effort went into the aesthetics by this point.

One of the factory bolts that are to mount the later model engine cover in place is in the correct location to mount the throttle cable bracket. This is the one shoddy part of this project - there is no further way to secure the bracket to the intake without either adding pieces of fabricating a bracket extension that would extend to another bolt. I have had no issues out of this setup so far, but I am very tempted by the prospect of modelling and 3d printing a piece that would fit around the ridges on the intake, glued into place, that could then further secure the bracket to prevent any rotation. That said - 2500 miles so far, so far so good.

Another shot of the same. I personally did not retain the EGR system, though there is an allocation in the TBSS intake that you could retain it if you wished to. You can always make a plate to block off the connection from the exhaust manifold to the hot side EGR tube to disable the system, leaving the valve in place to prevent a code from being thrown. Alternatively, you could dremel out the opening in the intake and get a brass fitting to heat and insert into the bolt hole provision in the intake and fully retain the system. In fact, you could likely heat and remove the threaded brass fitting from your factory intake to then insert it back into the TBSS intake. For myself, I deleted all of it and installed shorty headers which had no EGR provision to begin with.