Quick update: first of all, I hope everyone had a great Xmas and got to spend some time with family and friends. If I don’t get back on here, I hope everyone has a safe and happy New Years too. Don’t drink and drive, not worth it. Call an Uber.

Back to my never ending trans change. I dropped the transfercase oil and put some new Amsoil ATF in. Did the rear and front differentials too. Then I changed the engine oil and filter. Spent more time flushing the trans lines and cooler in radiator. I wasn’t gonna call that done until it was clear and clean. The pump flush I had used didn’t have enough pressure. I ended up filling my ac line flush gun with ATF and using 100psi and started getting more debris. Then used brake cleaner followed by a blow gun. After 4 times, 2 each way, I’m not getting anything out the lines anymore. I’m confident enough to hook up the trans lines to trans and install cooler.

Not sure if I posted or not, but I removed drives side exhaust manifold.

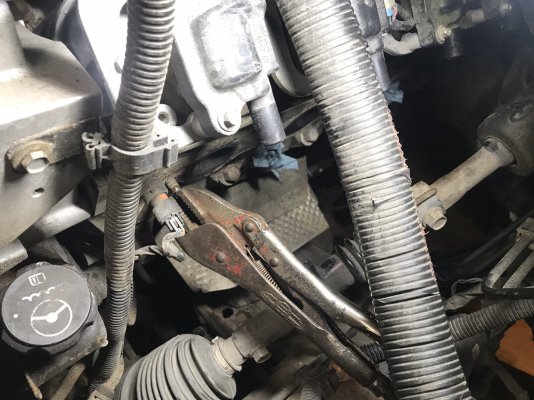

This side had a broken bolt on the front.

I was able to grab it with vise grips so I heated the head with propane torch and backed the broken bolt out.

Then I cleaned the head and chased the bolt holes. Blew out the threaded holes and sandblasted the manifold. Then I heated the manifold and removed then replaced the studs for mid pipe. After that I slapped on some POR15 high heat paint.

Then the passenger side came off. It was a little harder to get at and also I had to heat the manifold around the bolts a lot more than the drivers side to get the bolts out. This side the rear most bolt was the one that broke. I didn’t have as much as the drivers side to grab with vise grips so I decided it was in my best interest to weld a nut to the protruding stud which heated the stud and also gave me a way to extract it. Sorry no pics, it was hard enough getting in there and took longer than I wanted so I was rushing.

Then I sandblasted manifold and heated up the first stud for mid pipe and snapped it off below flush. SOAB!! Spent the next 2 hrs burning drill bits and trying to extract the stud. After not being able to pull the stud, I ended up drilling it all the way out and when I was about to get into the threads, I was able to remove.

I said screw it and ran my die over the remaining 2 studs. I’m not spending that kinda time removing broken studs, besides, this side I was able to get the nuts off without having to cut studs.

So I cleaned manifold with brake cleaner and slapped on the paint.

While manifold was curing, I wanted to get drive shafts back together. I did the front shaft first. Popped the u-joints in and it’s ready to go.

Did the rear shaft next. Front joint went in and got the yoke attached. Put the rear in and when I was setting the cap to put the clip in, the opposite cap busted. Wth? It was in and I wasn’t hitting that side. Had to remove the joint and now I need to get another one.

I’ve never had that happen before while installing new one. Had it happen removing old ones. Before I can put front shaft in, I need to get drivers side manifold on. I wanna first say, these are the only manifold gaskets IMO. I’d never use anything but these.

That being said, manifold is on.

Today the passenger side is going on and hopefully the mid pipe will be on and truck back on the ground. Fingers crossed.

Sent from my iPhone using Tapatalk