Complete with upgrade. I have a few notes... but first.

WOW you did an AMAZING job refurbishing the junction block! It was LIKE NEW. I was going to have to resort to eBay to do this project but you saved me all the grief of fiddling around, cleaning up, and rebuilding the harness. Thanks!!!

I got the high speed fan control to work

Wiring

C2 Pin 33 is AC Recirc mode on the 2001, on the 2005 it's high speed fan control.

DON'T cut the wire... de-pin it from the harness. It's going to be a green wire. Then tuck it up in the wire loom incase you want to revert to AC recirc mode.

Next populate that pin with a blue wire.

Track the PCM wire loom up into the junction block. I like to maintain factory routing.

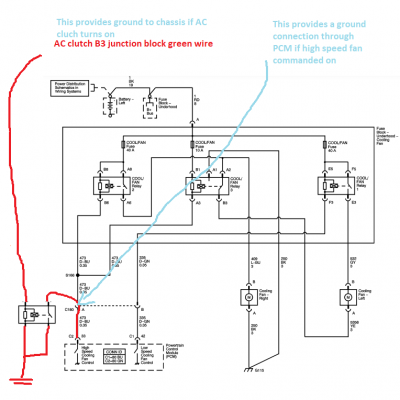

I made another wire connect to the AC relay as shown in image below. Then it connects through the two pin connector (the other contact being for low speed fans).

View attachment 453290

Tuning

View attachment 453289

these are settings from 2001. Change the Recirculation fitted setting to "Fan #2".

This switches the DIO in the PCM to logic for fan instead of logic for Recirculation. Note the recirculation door seems to still work. However, I think there's a boost pressure mode for the AC. I've not quite figured it out. Whatever it is it's now disabled. If anybody knows more about "Recirculation Fitted" mode... Let me know I'd be interested to understand what I disabled.

Additionally, you CANNOT splice into the recirculation wire and onto the relays for fan control. This divides the voltage and the relays won't trigger.

I believe but couldn't confirm that the setting below that "Type Fitted" if changed to "Serial Cycling" may also read the pressure. You could in theory then divide the reference voltage in half and send it in Pin 14 C2? and get the fans to kick on when AC is enabled. However, my truck wouldn't start with that setting and I'm quite positive the AC wouldn't work even if it had...

A note on the low speed trigger wire

C1 Pin 42 is not populated on the 2001, on the 2005 it's low speed fans.

Populate that with a green wire (

@ScottyBoy) did that for me already.

Make the wire long enough to trace the PCM harness back through and into the junction block.

Take these two wires and put them into a two wire connector. (I more or less revised

@ScottyBoy's harness to do this).

A note on the AC clutch relay connected to B3 clutch supply voltage

It maybe prudent to put a slightly higher gauge wire on there. Say 14 gauge. Reason is, that's a 10 amp circuit. Granted the AC clutch is something like 6 ohms so most of the current should flow through it... but if there's a fault, say the coil in the relay for the fans shorts out it won't fail safe. That small gauge wire could heat up a bit before the fuse ever pops. It's splitting hairs.

Possibly revise trigger for AC fan mode

I'm only saying this because I studied the factory service manual for hours trying to optimize things. I think I may have come across a wire possibly available under the hood that / PCM pinout even that indicates if the AC is commanded on. That would be better as the AC clutch isn't always on when the AC is on. This causes the fan to cycle quite a bit which isn't ideal for hardware. Will it tolerate it? Yeah probably fine... but will it last as long that way... most likely not. It'll prematurely wear out the harness and fans themselves due to spike in current every time the fans go on and off (it's literally a wave in the wire).

Back to relays...

Typically relays have the control side (coil) on a separate / isolated circuit to help protect the delicate control systems. I see even GM isn't doing that now in this fan design. I digress though...

I think that's about it. I fiddled with this from sun up till sun down two days in a row. In short, it'd be a good case for a stand alone fan controller. GM got super janky with this PCM. It shouldn't have an AC controller... that should be in the head unit for the AC if at all. AC takes a couple switches to run and that's about it.

I digress again... lol hard to suppress my engineer brain. I've done a bit of design work like this but for aircraft.