The angle of the arm doesn't really affect the wheel rate (aka stiffness) of the suspension - it's all about the motion ratio. See figure below. All of the lowering control arms I'm aware of maintain the same motion ratio as stock so the truck rides the same before and after being lowered.@stab6902, I am curious about your first comment, about the lowering arms not helping the suspension compress… if the lower arm was 2” more level would it not be easier to compress the shock vs if they are at a steep angle like now?

Also I’m wondering if the lowering lower control arms move the lower shock mount position further towards the wheel/tire, which if it did I would imagine that would also help with having more leverage to compress the shock, no?

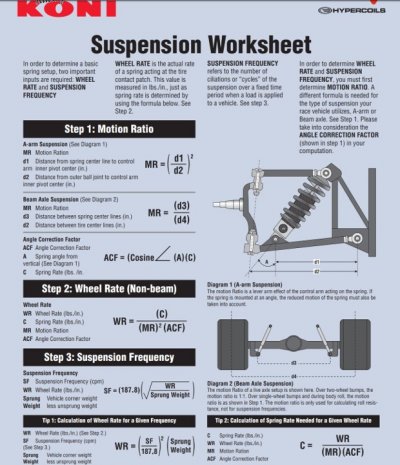

To make your suspension "softer," you'd want to move the lower shock mount closer to your lower control arm bushings (reducing d1 according to the Suspension Worksheet). A little bit goes a long way, since you square [d1/d2]. This would give your tire more leverage on the coilover assembly.

I don't have any parts in front of me, so I had to guess based on pictures, but it appears as though the motion ratios for the K2XX and T1XX trucks are pretty similar. Therefore, it's kind of surprising to me that you find the shocks to be super stiff. If anyone could share actual measurements, we could be a lot more accurate.

If you're dedicated to making this work, it looks like you could buy some lowering control arms and drill some new lower mounting holes closer to the bushings (last figure). You'd need some precise lower control arm measurements, spring rates, and corner weights to guess how much to move the holes, but moving them as far towards the bushings as practical would probably be an OK starting point. You'd also have to be sure not to reduce the strength of the arms in doing this... welding in reinforcements where you remove material (if necessary) would be advisable.