I don't have any advice about the booster change. Some scanners will let you reset the LTFTs; maybe disconnecting the battery and touching the cable terminal ends together would also do that. If not, the LTFTs should adjust over time.

Seems to me the vacuum hose connection at the booster might have some kind of check valve in it, but I'm not quite sure. That might be something to check if it's there.

I replaced the check valve to booster grommet (with one from a universal multi-pack I had on hand) and that corrected my STFTs the same way plugging the booster hose did. Afterwards, I purchased a new (genuine AC Delco) check valve and grommet and installed with no new improvements.

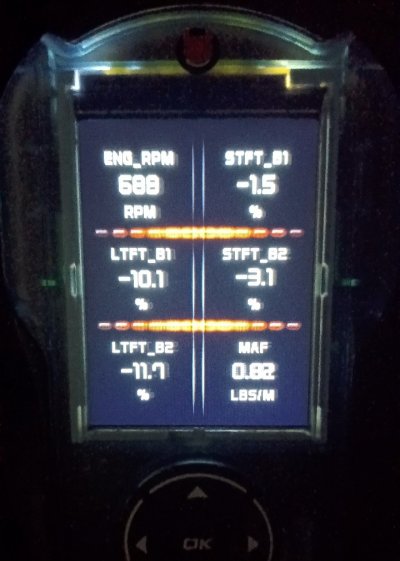

It seems my check valve grommet was the culprit for my wild fuel trims. I'll post an image of LTFTs and STFTs next update, which should give time for the numbers to adjust if that's the end of my vacuum leak.

I still have suspicions of my brake booster, but it passes all the tests and it seems like fuel trims temporarily rising from excessive (3-10 times, let's say) brake pumping may just be normal for vacuum boosted brakes?

Yeah, it was a pain but I managed to get all the carbon cleaned out and return to normal status. Just make sure you have no restrictions through the inlet and outlet line of your OCC.

I would use a vacuum pump and perform a leak down test of your brake booster. Not saying the booster is good or bad, but you said your STFT returned to normal after plugging the hose, but those values are constantly changing and I don't believe that's an accurate judge of your issue. The STFT is a fine adjustment if you will of the "coarse adjustment" of the LTFT. You will need to check and/or bypass the check valve for that test.

Have you checked the throttle butterfly for any "looseness" or "wiggle"? Sometimes the gears wear in the TB mechanism.

For those in the know, I haven't had mine for long enough so I haven't dived in very deep yet, but I assume these throttle bodies have an IAC or Idle Air Control valve or mechanism? Would this be integrated or a seperate part?

When I hear of throttle fluctuations on a MAF engine, I start to think of bad or dirty MAF, worn throttle gears, faulty ignition but you checked that, or even a fuel issue.

Just to rule it out, and I hate to ask, but removing an easy to reach plug and verify the plug type/# is a good start. Cold air is more dense and harder to light off the fuel mixture.

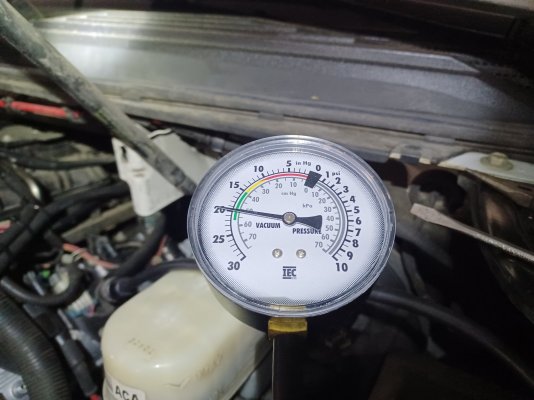

I would also want to know what the vacuum looks like with a gauge. Does the needle fluctuate rapidly or is it steady but with normal, slight varying movements?

Does your Envoy have the 5.3 V8?

Next time I update, I'll upload images of the fuel trims again--post check valve replacement (see above).

I'm not as familiar with Envoys. I know the Denali trims of those makes came with 5.3 engines, but I'm not sure they are exactly the same as the 5.3s in the 07-14 full size SUV/truck lineup. If by "integrated" you mean different from the cabled throttle bodies of older vehicles, then I think the answer is yes. I'm pretty sure I can replace my throttle body sensor (which incorporates the IAC or equivalent for electronic TBs), albeit with a potential relearn procedure to follow, but it's attached to the side of the TB with direct internal gear contact to the TB--*I believe*.

I don't know that I've conducted thorough testing of my MAF, TB, or MAP, but I have cleaned all of them. I wouldn't be surprised to find an issue with my throttle body or MAP sensor, so I'll be looking further into those areas next.

When I plugged my booster hose with the vacuum gauge at idle, the needle was steady at/around the 20 mark. I can't say if the needle moved when I revved my engine.