Hello, colleagues!

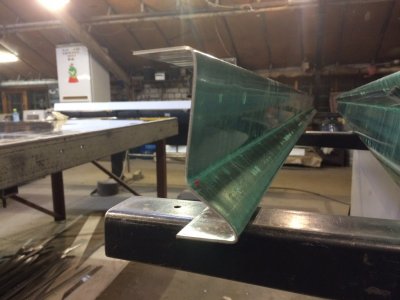

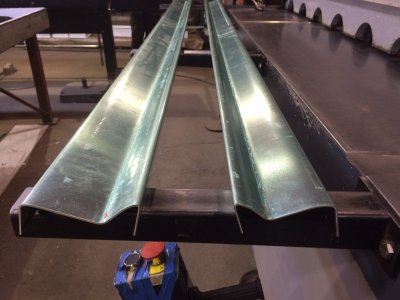

My second job after the acquisition of Suburban 1999 was the AISI 310 stainless steel bumper.

I started with the front bumper.

It's no secret that the chrome on our bumpers clumps and the bumpers corrode to through holes.

The situation needs to be corrected.

It's very difficult to repeat the design of GM engineers. But to get close to their design with a shiny surface is my job.

I used a 3mm-thick sheet from Outokumpu (Finland) with a mirror surface.

I calculated the dimensions.

Cut the sheet on the guillotine.

Bent it.

Bent it along the cut out sectors and welded it with welding in argon.

Chronology of work in pictures:

Translated with www.DeepL.com/Translator (free version)

My second job after the acquisition of Suburban 1999 was the AISI 310 stainless steel bumper.

I started with the front bumper.

It's no secret that the chrome on our bumpers clumps and the bumpers corrode to through holes.

The situation needs to be corrected.

It's very difficult to repeat the design of GM engineers. But to get close to their design with a shiny surface is my job.

I used a 3mm-thick sheet from Outokumpu (Finland) with a mirror surface.

I calculated the dimensions.

Cut the sheet on the guillotine.

Bent it.

Bent it along the cut out sectors and welded it with welding in argon.

Chronology of work in pictures:

Translated with www.DeepL.com/Translator (free version)