Tbruz

Full Access Member

1997 Tahoe, 5.7 engine.

My OCD is acting up and I'm tired of seeing my temp gauge read about three hashmarks too low for the actual temp(verified actual temp at 187 with scanner).

Each has hash is about 14 degrees so the indicated temp is showing between 140-150.

Today I replaced the coolant gauge temp sender in the DS cylinder head with a AC Delco part with no change; I then used a Standard Motor part, again with no change; Both read exactly the same as the original suspect part, 140-150.

Grounding out the single signal wire to the gauge itself causes the gauge to peg above the 260 mark so the gauge itself is working at the extreme end.

any ideas or suggestion besides "live with it" or "get over it"

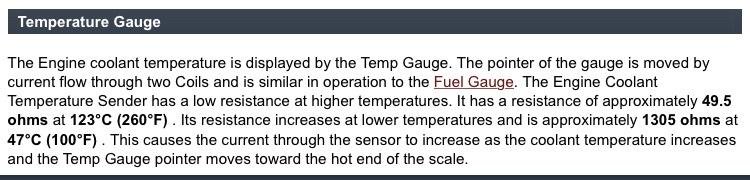

Is there a test/calibration procedure like "X "resistance should indicate "Y" position on the gauge itself?

I realize its an insignificant issue and not really a problem; its just stuck inside my head now.

Thanks in advance

Tbruz

My OCD is acting up and I'm tired of seeing my temp gauge read about three hashmarks too low for the actual temp(verified actual temp at 187 with scanner).

Each has hash is about 14 degrees so the indicated temp is showing between 140-150.

Today I replaced the coolant gauge temp sender in the DS cylinder head with a AC Delco part with no change; I then used a Standard Motor part, again with no change; Both read exactly the same as the original suspect part, 140-150.

Grounding out the single signal wire to the gauge itself causes the gauge to peg above the 260 mark so the gauge itself is working at the extreme end.

any ideas or suggestion besides "live with it" or "get over it"

Is there a test/calibration procedure like "X "resistance should indicate "Y" position on the gauge itself?

I realize its an insignificant issue and not really a problem; its just stuck inside my head now.

Thanks in advance

Tbruz