zyka1

TYF Newbie

- Joined

- Sep 27, 2010

- Posts

- 23

- Reaction score

- 0

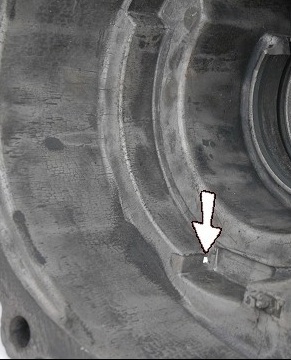

Most of you know the problem, dumb design, a broken clip that allows the steel pump to rub a hole in the aluminum case, (see below).

Question one- My question is can this be welded??

Many say it cant, but I found this article that makes it seem possible. ( http://www.magnesium-elektron.com/data/downloads/DS250JO.PDF)

Using a new pump saver wont seal the hole, or will it, wont this still leave you with a leaking T/case fuild problem.

Question Two - Has anybody else had a one hundered % fix for this problem ??

Question one- My question is can this be welded??

Many say it cant, but I found this article that makes it seem possible. ( http://www.magnesium-elektron.com/data/downloads/DS250JO.PDF)

Using a new pump saver wont seal the hole, or will it, wont this still leave you with a leaking T/case fuild problem.

Question Two - Has anybody else had a one hundered % fix for this problem ??