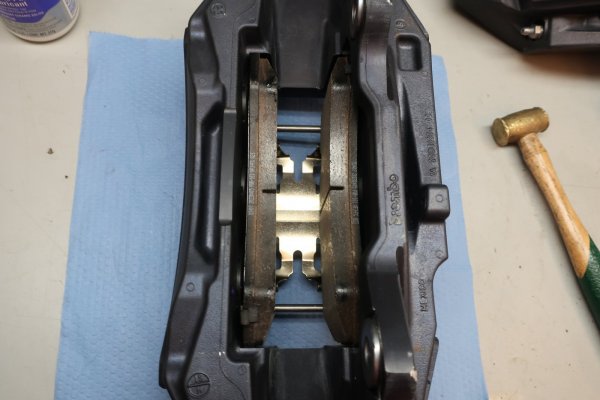

Alright, we have established that the new calipers are too fat for the stock wheels to fit.

Spacers and longer lug studs are needed.

The front lug studs have the following dimensions:

GM 11603331

Thread: M14x1.5

Knurl dia: 15.8mm (0.623")

Shoulder length: 0.638" (16.2mm)

Thread length: 31mm

Underhead length: 65.405mm (2.575")

Quick start nose: Yes

Of these dimensions, Knurl diameter and underhead length are the two that matter most.

I dug around on the internet and came up with these lug studs:

Dorman 610-530

Thread: M14x1.5

Knurl dia: 15.9mm (0.625")

Shoulder length: 1.008" (16.2mm)

Thread length: 48.4mm

Underhead length: 78mm (3.07")

Quick start nose: No

I ordered 12 of them.

Dorman 610-530.1 lug studs. I found these spec'd out for the rear of a Ford F350 dually.

I have new lug studs. OK, great. Now to change them. Should not be too bad. AllDataDIY service manual states (paraphrasing) remove brake caliper, remove brake rotor, press out old stud with ball joint press, use lug nut and stack of washers to pull new stud in.

WRONG.

In

So

Many

Ways...

I wasted time searching for different lug stud removal and installation tools. Ball joint press was a no-brainer, as I already had one. Only tools I saw for installation pretty much replaced the stack of washers with a sleeve and bearing. I screwed up and took to heart an article I read. It stated that pulling the new stud in with a lug nut and stack of washers can stretch/damage the threads on the stud. A better idea is to use a ball joint separator to push the stud in from behind the wheel flange.

That seemed like a REALLY good idea to me.

Having done this, that was a really BAD idea. Rereading the article, the author was working on a Toyota Corolla. M12 lug studs. GMT900's use M14 lug studs.

Idiot

Anyway, I got the calipers and rotors back off. As an aside, I am glad I did NOT use the M14x2.0 - 40mm TTY mounting bolts. I would have had to buy another set.

Looking at the casting of the spindle, I had the most room to work with in terms of using the ball joint removal tool by placing the lug stud in question at about the 10-11 o'clock position. Until I realized the base of my ball joint tool was too thick to fit behind the wheel flange.

I tried various stupid ideas that reinforced my knowledge of offset vectors. IE angled push launched spacer at my head.

Staring at it long enough, I decided the only thing I could do was unbolt the hub and see if I had enough clearance then.

Luckily, I did. The outer CV joint had enough in-n-out movement to allow me to **** the wheel bearing hub to JUST get enough clearance to get the base of the ball joint press behind the wheel flange. Mind you, those wheel hub bolts were quite tight!

Passenger's side front wheel bearing hub unbolted and cocked for clearance.

Using the ball joint press was not too bad to press out the original lug studs. The base did not sit 100% flat on the back of the wheel flange, but it was close enough. I just had to ensure the tip of the forcing screw was centered on the round nose of the stud. I used my battery impact to drive the forcing screw and push the stud out. Did not slip off for any of the 12 studs.

Chinesium ball joint press used to press the old lug studs out of the wheel flange.

All this extra work does beg the question: why didn't I just beat the old lug studs out with a hammer? Because my luck says the 154,*** mile wheel bearings would not like it. Also, I don't know if there would have been sufficient room to slide the new lug studs into the wheel flange for installation.

Installing the new longer lug studs was a b*tch in high heels. In theory, the ball joint separator would work fine to push the studs in. In practice, not so much.

I learned a few things along the way:

-lubricate splines with AeroKroil to assist pulling in

-start stud with just the ball joint separator, then put a large nut behind the head of the stud and push it home. This is due to how the tool works at a decreasing angle

-getting the large nut spacer to stay on the back of the stud and not come flying out at me was hit or miss. I got hit alot.

-clean and relubricate the forcing screw threads with synthetic wheel bearing grease for each lug stud

-new curse words to assist the tool

I finally got all 12 lug studs in. Though the tool suffered. Badly.

I was very concerned about completely stripping the threads on the forcing screw, so I did not let the impact linger when I thought the stud was seated at the wheel flange. As a little insurance, I set up a spacer, washer, and lug nut on each stud. Then gave the lug nut a blast from the impact. Just to ensure the new lug studs were fully seated.

Using ball joint separator tool to initially start the new lug studs.

Spacer nut behind the head of the new lug stud to help the ball joint separator fully seat the stud. And occasionally shoot out at my head.