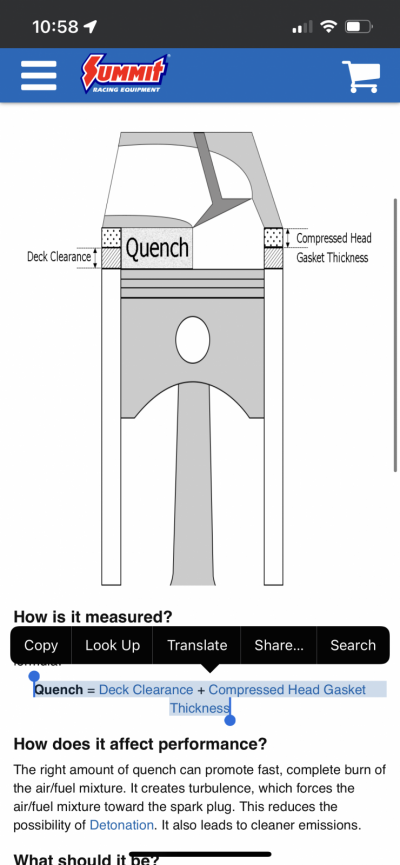

Ok ok hang on, so summit says it’s clearance plus gasket thicccness. If the deck clearance is +.008 wouldn’t that be .008+.041=.049?

Or because it’s positively out of the cylinder, meaning sticking up like a hard ****** .008 that means you need to subtract it because it obviously makes the quench volume less. Meaning .008-.041=.033/danger. I think this is correct and is what my initial thoughts were but then the summit wording got my panties in a bunch.

So if that’s the case the .041 gaskets are probably too thin to be safe but your saying I could check with modeling clay how? Put the heads on with clay on the piston and turn the crank over sinking the valves into the clay and then pull the heads off and measure compressed clay thicccness?

Thank you for your patients kind sir.

You have NEGATIVE deck clearance when the piston comes outta the hole. So, you subtract .008" or whatever your clearance measures out to be. I have a bad habit of calling it "piston height", which is not technically correct. Piston height is the measurement from the center of the pin to the top of the piston.

Modeling clay lets you see the quench height but it's primarily for seeing PTV clearance. So, it's a two-fold benefit. I used an old stock gasket (.051" compressed), put some modeling clay on top of the piston (smeared a light coat of oil on piston and in chamber) and cinched the head down with old head bolts. I didn't fully torque them, obviously, but got kinda close. I turned the crank slowly by hand a couple times then pulled the head. I

carefully sliced the clay with an X-Acto knife (using more pushing of the blade than dragging it) and measured the cut cross sections at the head surface and at each valve with a digital caliper. You have to use modeling clay- not Play-Doh, etc. I subtracted .006" from my measurements since I was planning on .045" gaskets.

OH! I forgot- you need to use solid lifters. I took apart two of my stock non-AFM lifters, flipped one of the pieces inside around (I don't recall the proper name of the piece) and reassembled them to make "solid" lifters.