Team,

Need help finding a replacement vent for the fuel tank. Also, how do you remove old vent and replace?

I've seen this called a vent and also a vent valve.

Dropped the fuel tank to inspect separate issue. Noticed in the aft of the fuel tank a problem with the vent (white plastic) which connects via a line to the EVAP canister.

A rodent chewed out the white plastic elbow (see photo). Need to find a replacement part.

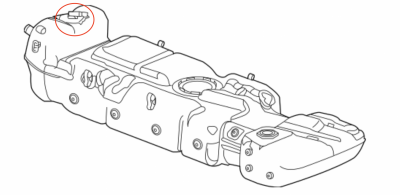

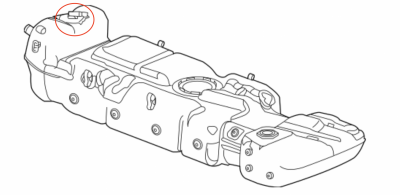

Also, want to confirm how to remove and replace old vent (in red circle in diagram) and install replacement.

Three images below: 1 - fuel tank diagram with red circle indicating location.

2 - close up of my tank's vent where you can see the chewed out section. within the chewed out portion of the white plastic elbow, it appears black because i stuck a black tube in there to see if it would fit.

3 - what a healthy vent should look like (screen shot from a 1A auto fuel pump video)

Thanks!

-Tom

Need help finding a replacement vent for the fuel tank. Also, how do you remove old vent and replace?

I've seen this called a vent and also a vent valve.

Dropped the fuel tank to inspect separate issue. Noticed in the aft of the fuel tank a problem with the vent (white plastic) which connects via a line to the EVAP canister.

A rodent chewed out the white plastic elbow (see photo). Need to find a replacement part.

Also, want to confirm how to remove and replace old vent (in red circle in diagram) and install replacement.

Three images below: 1 - fuel tank diagram with red circle indicating location.

2 - close up of my tank's vent where you can see the chewed out section. within the chewed out portion of the white plastic elbow, it appears black because i stuck a black tube in there to see if it would fit.

3 - what a healthy vent should look like (screen shot from a 1A auto fuel pump video)

Thanks!

-Tom