You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2012 Yukon XL Denali 6.2L Cam Swap Thread

- Thread starter Geotrash

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

iamdub

Full Access Member

I highly doubt your oil pump was the reason for this. If you had good oil pressure, you were getting oil to where it needed to go. Looks like a defective part to me.

This is what I'm thinking. Maybe a flaw in the hardening process?

randeez

Full Access Member

I highly doubt your oil pump was the reason for this. If you had good oil pressure, you were getting oil to where it needed to go. Looks like a defective part to me.

x2 ive ran engines with zero oil in them and not ended up that bad

Oil pressure was definitely lower than before the swap so something was off, but I agree, the engine was likely getting enough oil. No issues anywhere else but the cam lobes. Even the cam bearings were fine, and the cam was dripping with oil when I pulled it out.I highly doubt your oil pump was the reason for this. If you had good oil pressure, you were getting oil to where it needed to go. Looks like a defective part to me.

Sent from my iPad using Tapatalk

New cam is in and the heads are back on. Timing marks are lined up and she’s getting ready to rock - hopefully later this week!

Sent from my iPad using Tapatalk

Sent from my iPad using Tapatalk

Also, the Fel-Pro Perma torque MLS head gaskets looked like new when I pulled them out, but I used new ones anyway. Any opinions about reusing them?

Sent from my iPad using Tapatalk

Sent from my iPad using Tapatalk

wjburken

Supporting Member

Agree. I’d find better places to try and save money. There is some money I can’t afford to save and this would be some of it.Nah always use new, never chance it on heads. So much work to get that far.

thompsoj22

Full Access Member

- Joined

- Jul 21, 2018

- Posts

- 689

- Reaction score

- 718

Got the driver’s side cylinder head off and found one bad lifter so far. It was the #5 exhaust. That also matches well with the cam lobe that was the most damaged. That said, to my eye, none of the other lifters look like the rollers are damaged at all.

Thoughts? I’m wondering if maybe a bit of grit got in there and stuck the roller. Either way though, the cam was definitely trashed. On most of the lobes in fact.

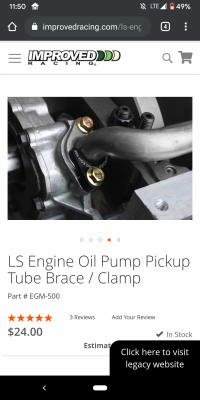

One more thing… When I installed the pick up tube into the new milling oil pump, the O-ring was a much more snug fit than the one I installed in the factory pump last time around. I’m wondering if even though I got the right red O-ring last time, if it was undersized.

Yup, Ill second the opinion of soft/defective cam, Possibly the hardened rollers started destroying the soft cam material from the first startup. Shame how our perception of "quality" is based upon a small companys intent of putting out a good product but you might have an employee with a F'it attitude on a monday/friday and somthing like this happens. This project educated me, And when i do need to reman our engine i will only use OEM components. No hacking intended, It is simply getting so hard to find quality that is real as opposed to simply a verbiage marketing strategy.

Similar threads

- Replies

- 21

- Views

- 5K

- Replies

- 1

- Views

- 4K

- Replies

- 20

- Views

- 11K