You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2012 Yukon XL Denali 6.2L Cam Swap Thread

- Thread starter Geotrash

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

wjburken

Supporting Member

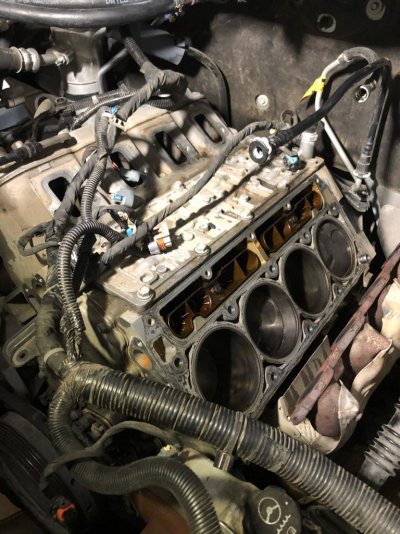

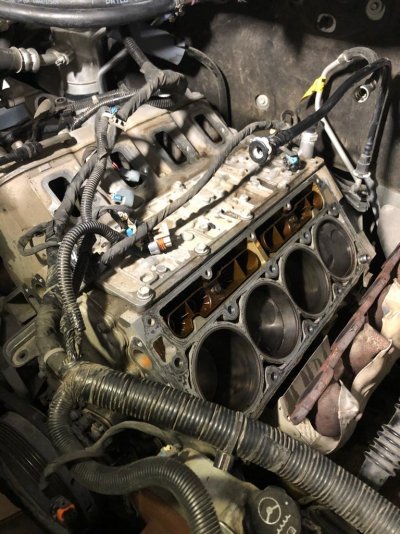

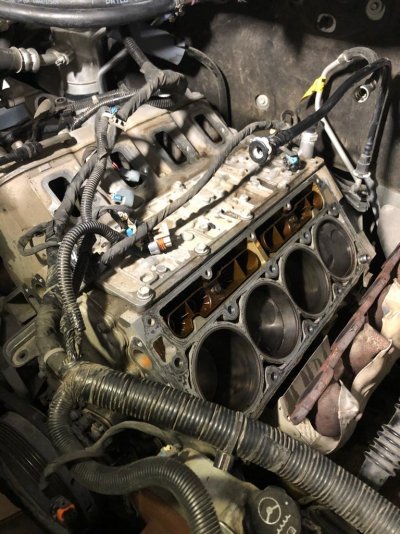

Made some progress today. Only had a few hours to work on it but got the front fascia off, coolant drained and the intake manifold off. Hope to get the heads off this week and over to the machine shop.

As an insurance policy I also ran a logging session with the Autocal v3 and also pulled the stock tune files off the ECM before starting the work. I realized that it would enable Black Bear to prepare a tune to get it up and running while it’s out of service, and then I can work with Steve Frost for a final in-person tune.

Sent from my iPad using Tapatalk

As an insurance policy I also ran a logging session with the Autocal v3 and also pulled the stock tune files off the ECM before starting the work. I realized that it would enable Black Bear to prepare a tune to get it up and running while it’s out of service, and then I can work with Steve Frost for a final in-person tune.

Sent from my iPad using Tapatalk

Had about an hour this evening to get the driver’s side cylinder head off. Seems strange to be taking apart a perfectly good engine, but also helpful to know that when it goes back together it will be better than new in many ways.

All of the parts look like new, all of the rollers on the lifters roll smooth as silk, so it’s good to know that it was well cared for. I got lucky on this side, and had no problems with the exhaust manifold bolts. Fingers crossed for the passenger’s side.

Question for you experts: I’m taking the heads into a machine shop to be milled down .0025, per recommendation from iamdub. Is there anything else you recommend that I have them do other than clean them up? I have new Viton seals for the valve stems I could have them install, and will be doing the new trunnion upgrade on my bench when I get them back, but would you recommend having them lap the valves or anything?

Sent from my iPhone using Tapatalk

All of the parts look like new, all of the rollers on the lifters roll smooth as silk, so it’s good to know that it was well cared for. I got lucky on this side, and had no problems with the exhaust manifold bolts. Fingers crossed for the passenger’s side.

Question for you experts: I’m taking the heads into a machine shop to be milled down .0025, per recommendation from iamdub. Is there anything else you recommend that I have them do other than clean them up? I have new Viton seals for the valve stems I could have them install, and will be doing the new trunnion upgrade on my bench when I get them back, but would you recommend having them lap the valves or anything?

Sent from my iPhone using Tapatalk

Just Fishing

Can't fix stupid

Both heads are off and headed to the machine shop this afternoon. Some lessons learned:

- Take both front wheels off and the wheel well liners out. You'll thank yourself.

- Chemical gasket remover foam works incredibly well. I was able to get all of the head gasket residue off the block without any abrasives. The stuff goes on with the tiny plastic bristle brush built onto the top of the can, sits for 30 minutes, and wipes off with a shop rag and very little elbow grease.

- The oil pan has to come off (dropped a few cm, anyway) to get the oil pump off. I'd hoped to be able to do it without dropping the pan, but can't get a wrench on the pickup tube bolt no matter what I try.

- The exhaust manifold bolts take time, patience and penetrating oil to remove without snapping one off. I was patient, and got very lucky.

- The manual says the exhaust manifold to flange bolts need to come out. I didn't need to do that. I used the plastic handle of a dead-blow hammer to wedge in between the manifold and the head to get the bottom row of head bolts out on both sides. Plenty of room.

- Take the head bolts out in the reverse order of installation, loosening them 1/4 turn each in sequence. Takes about 15 minutes per head to do it this way, but reduces the chances of aluminum head warpage and cracking.

Jason in DLH

Cheeseburger and Fries

Nice build!

Since you’re so deep into it already....

Mind as well just go ahead with a bore and stroke. I believe you could safely get a 427 out of the block.

Since you’re so deep into it already....

Mind as well just go ahead with a bore and stroke. I believe you could safely get a 427 out of the block.

Jason in DLH

Cheeseburger and Fries

kbuskill

***CAUTION*** I do my own stunts!

Had about an hour this evening to get the driver’s side cylinder head off. Seems strange to be taking apart a perfectly good engine, but also helpful to know that when it goes back together it will be better than new in many ways.

All of the parts look like new, all of the rollers on the lifters roll smooth as silk, so it’s good to know that it was well cared for. I got lucky on this side, and had no problems with the exhaust manifold bolts. Fingers crossed for the passenger’s side.

Question for you experts: I’m taking the heads into a machine shop to be milled down .0025, per recommendation from iamdub. Is there anything else you recommend that I have them do other than clean them up? I have new Viton seals for the valve stems I could have them install, and will be doing the new trunnion upgrade on my bench when I get them back, but would you recommend having them lap the valves or anything?

Sent from my iPhone using Tapatalk

Just saw this...

My recommendation would be to have the machine shop pull a vacuum on the valves to make sure they are all sealing properly. If they are sealing well then there is no need to lap the valves.

I always have them Magnaflux the heads to make sure they aren't cracked BUT I have always pulled heads because of blown head gaskets.

Similar threads

- Replies

- 17

- Views

- 2K

- Replies

- 1

- Views

- 3K

- Replies

- 20

- Views

- 11K