DougAMiller

Full Access Member

So, I am rethinking installing the Jimmi Jammers. I looked up reviews on them and they get great reviews, however, almost all are "these are great, now I don't have to worry about my car being stolen again". When I looked only at reviews of people who reported about having another theft attempt, 2 out of 3 said it barely slowed the thief down, only one said it stopped them. Apparently, the metal plate can be bent enough to still push the lock cylinder out where it can be turned if you're a bit more aggressive with it.

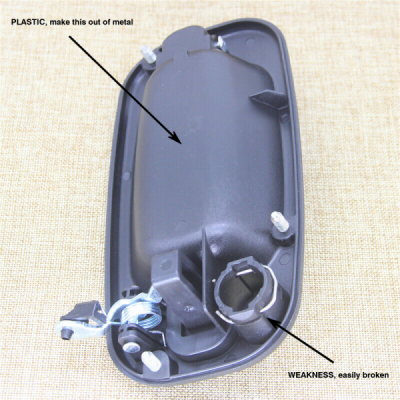

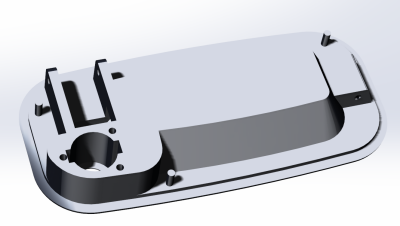

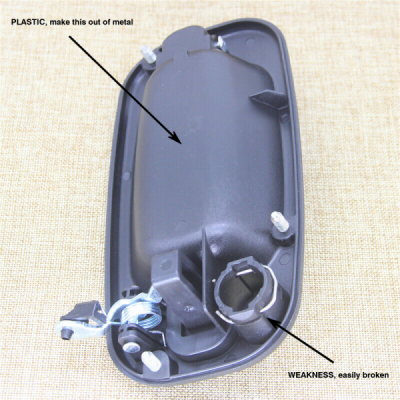

So, my engineer brain started thinking about what it would take to really stop this kind of attack, and I decided that what is needed is to replace the baseplate of the door handle with one made out of metal so they can't break the lock cylinder out of the plastic. This shouldn't be too difficult to CNC out of 7075 aluminum, have it painted and move all of the hardware from the plastic part to the metal one. In fact, it could be simplified on the back side, as a lot of the detail there is just hollowing out to save material costs. By not hollowing it out, it will be cheaper to machine and also be stronger. As an additional level of security, the C-clip that locks the lock cylinder in place can be replaced with a bolted-in metal plate. I can leave enough material around the lock cylinder hole to drill and tap three holes to bolt a steel plate over it.

I think I'm going to grab a handle off ebay, you can get one for $10 or less, and model it in SolidWorks, then send the design off to a machine shop and get a quote.

So, my engineer brain started thinking about what it would take to really stop this kind of attack, and I decided that what is needed is to replace the baseplate of the door handle with one made out of metal so they can't break the lock cylinder out of the plastic. This shouldn't be too difficult to CNC out of 7075 aluminum, have it painted and move all of the hardware from the plastic part to the metal one. In fact, it could be simplified on the back side, as a lot of the detail there is just hollowing out to save material costs. By not hollowing it out, it will be cheaper to machine and also be stronger. As an additional level of security, the C-clip that locks the lock cylinder in place can be replaced with a bolted-in metal plate. I can leave enough material around the lock cylinder hole to drill and tap three holes to bolt a steel plate over it.

I think I'm going to grab a handle off ebay, you can get one for $10 or less, and model it in SolidWorks, then send the design off to a machine shop and get a quote.