Made some progress yesterday. First some mundane things to deal with;

Broken exhaust bolt standing up for easy removal. Heat, penetrating oil, and a couple smacks with a hammer had this one ready to just pull out with vice grips.

This one was flush with the deck and had to be drilled, heated, penetrated, hammered, and finally extracted with a screw extractor.

Oddly I wasn't prepared for how light these cylinder heads are.

Block is nearly ready for final cleaning and then assembly. I managed to pull the harmonic balancer with an antique two jaw puller by using a combination of flat pry bars for the jaws to latch onto behind the pulley.

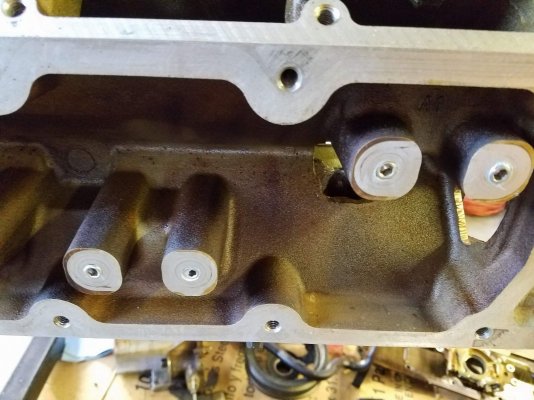

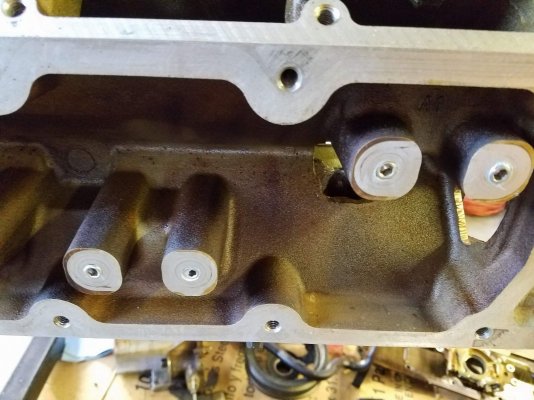

And finally the AFM oil towers plugged.

My oil pan is nasty and will take some cleaning. Oil on the outside, sludge piled up inside. I didn't get a perfect clean used engine. I wish I could afford to fix this thing up good as new so for now I'll have to follow the old programming adage: never test for an error condition you don't know how to handle.