iamdub

Full Access Member

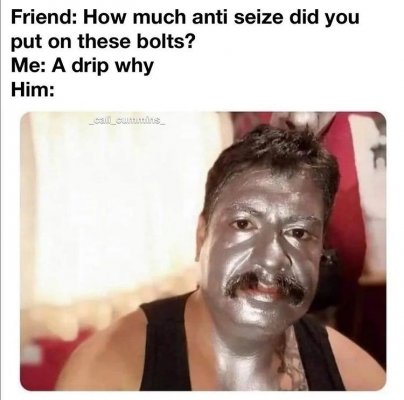

+1 for anti-seize. I've always used copper. Squirt a little on the bottom end of the threads and spin the plug with my finger holding the blob to spread it and push it down into the threads. I've replaced hundreds of plugs and never a problem.