You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Catch can flow discussion

- Thread starter iamdub

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

George B

¯\_(ツ)_/¯

@iamdub it’s hard to get a good picture. Mine doesn’t have the inlet or the outlet labeled but as you and I discussed, I’m coming out of the valve cover into the port that has the little brass filter and then it leaves the can through the unfiltered port to the intake.

I did notice my hose running to the Intake is collapsed and flat so I’ll have to replace that tomorrow

I did notice my hose running to the Intake is collapsed and flat so I’ll have to replace that tomorrow

Attachments

iamdub

Full Access Member

@iamdub it’s hard to get a good picture. Mine doesn’t have the inlet or the outlet labeled but as you and I discussed, I’m coming out of the valve cover into the port that has the little brass filter and then it leaves the can through the unfiltered port to the intake.

Thanks for checking that! You should've stuck a scouring pad on there while you had it open!

I might just see if I can remove or paint over the labels on this one so I'd feel better about "hooking it up backwards"

I did notice my hose running to the Intake is collapsed and flat so I’ll have to replace that tomorrow

What hose did you use? Is it fuel rated? The wrong hose can dissolve and get soft from the inside out. It'd be best to keep particles of rubber out of your engine.

George B

¯\_(ツ)_/¯

It is fuel rated hose but it must be kind of thin walled.What hose did you use? Is it fuel rated? The wrong hose can dissolve and get soft from the inside out. It'd be best to keep particles of rubber out of your engine.

Just Fishing

Can't fix stupid

My main experience would be with the drying of compressed air via my garage air system.

To get the water to seperate from freshly compressed air.

I have an overly complex drying setup that uses mostly distance from the air compressor to cool the air.

That alone catches a bit of water.

From there it's about using gravity to help that water separate.

So i have a series of vertical pathways, looks like a cage going up and down.

That serves to also further cool and give that water even more surface to stick to and separate from the air.

Place for the water to settle at the bottom of each rise, and of course a manual drain.

Then finally you want to spin that air via the air drier, filter, and regulator.

I get very little water in that final drier, even when running the compressor hard with something like my basting cabinet.

With our cars, we have basically the same idea, hot air mixing with oil splash and going out through the pcv.

It doesn't appear to be nearly as difficult to separate the two, but i went with the same basic idea.

Try to cool the air, make the oil fight a little gravity, and did my best to try and force the air to spin.

I took a cheap amazon catch can that had a design that had caps that are held on by a bunch of screws.

If i had to screw my top or bottom on, it might fk with my overly complex baffle system... lol

I made a chamber at the bottom, the inlet/valve cover side has a little aluminum tube to force the air to the bottom of the can.

Then the first baffle to help screen the air.

Then the second chamber where i made an aluminum fan or sorts.

Idea being that it forces a little spin to the air.

I doubt in practice it does exactly that, probably just more surface area for the oil to stick to..

Then the final chamber full of the scrubber mesh, mostly to force the air through and to give that oil somewhere to stick.

In my setup, i have my catch can mounted in the front of the engine bay, in the space where the second battery would go.

I also added a second catch can in series to see how well the first one works.

The second can never catches any oil, just water...

And that water never shows up unless it's winter/cold outside.

To get the water to seperate from freshly compressed air.

I have an overly complex drying setup that uses mostly distance from the air compressor to cool the air.

That alone catches a bit of water.

From there it's about using gravity to help that water separate.

So i have a series of vertical pathways, looks like a cage going up and down.

That serves to also further cool and give that water even more surface to stick to and separate from the air.

Place for the water to settle at the bottom of each rise, and of course a manual drain.

Then finally you want to spin that air via the air drier, filter, and regulator.

I get very little water in that final drier, even when running the compressor hard with something like my basting cabinet.

With our cars, we have basically the same idea, hot air mixing with oil splash and going out through the pcv.

It doesn't appear to be nearly as difficult to separate the two, but i went with the same basic idea.

Try to cool the air, make the oil fight a little gravity, and did my best to try and force the air to spin.

I took a cheap amazon catch can that had a design that had caps that are held on by a bunch of screws.

If i had to screw my top or bottom on, it might fk with my overly complex baffle system... lol

I made a chamber at the bottom, the inlet/valve cover side has a little aluminum tube to force the air to the bottom of the can.

Then the first baffle to help screen the air.

Then the second chamber where i made an aluminum fan or sorts.

Idea being that it forces a little spin to the air.

I doubt in practice it does exactly that, probably just more surface area for the oil to stick to..

Then the final chamber full of the scrubber mesh, mostly to force the air through and to give that oil somewhere to stick.

In my setup, i have my catch can mounted in the front of the engine bay, in the space where the second battery would go.

I also added a second catch can in series to see how well the first one works.

The second can never catches any oil, just water...

And that water never shows up unless it's winter/cold outside.

Just Fishing

Can't fix stupid

I'll also note that my catch can in the tahoe, i doubt that I'll ever make another one like that with the little fan chamber.

In the jeep i went with a square catch can, the inlet tube, bottom chamber, and then full of stainless scrubbers!

My boat doesn't have a pcv nor does it use the intake to vacuum the crank case.

Just open vents on both sides of the valve covers.

It will get a different style of a catch can later, mostly to keep the engine area clean, and to prevent that oil stank.

In the jeep i went with a square catch can, the inlet tube, bottom chamber, and then full of stainless scrubbers!

My boat doesn't have a pcv nor does it use the intake to vacuum the crank case.

Just open vents on both sides of the valve covers.

It will get a different style of a catch can later, mostly to keep the engine area clean, and to prevent that oil stank.

iamdub

Full Access Member

It is fuel rated hose but it must be kind of thin walled.

I've had "meh" luck with fuel/vapor rated hoses, mostly the bulk stuff bought by-the-foot at the chain stores. Probably a source quality thing. It seems to be sure, you have to get fuel submersion rated. Kinda ridiculous for PCV, though. I like to nab factory PCV hoses off cars at the salvage yard. Cheap and guaranteed to last for 100K+ miles.

iamdub

Full Access Member

My main experience would be with the drying of compressed air via my garage air system.

To get the water to seperate from freshly compressed air.

I have an overly complex drying setup that uses mostly distance from the air compressor to cool the air.

That alone catches a bit of water.

From there it's about using gravity to help that water separate.

So i have a series of vertical pathways, looks like a cage going up and down.

That serves to also further cool and give that water even more surface to stick to and separate from the air.

Place for the water to settle at the bottom of each rise, and of course a manual drain.

Then finally you want to spin that air via the air drier, filter, and regulator.

I get very little water in that final drier, even when running the compressor hard with something like my basting cabinet.

With our cars, we have basically the same idea, hot air mixing with oil splash and going out through the pcv.

It doesn't appear to be nearly as difficult to separate the two, but i went with the same basic idea.

Try to cool the air, make the oil fight a little gravity, and did my best to try and force the air to spin.

I took a cheap amazon catch can that had a design that had caps that are held on by a bunch of screws.

If i had to screw my top or bottom on, it might fk with my overly complex baffle system... lol

I made a chamber at the bottom, the inlet/valve cover side has a little aluminum tube to force the air to the bottom of the can.

Then the first baffle to help screen the air.

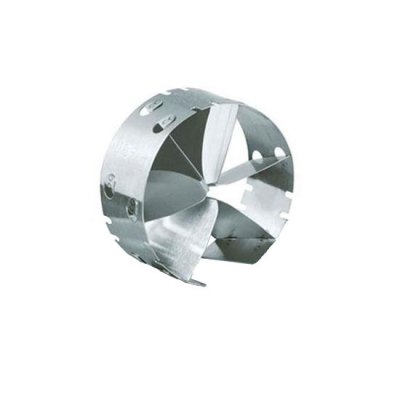

Then the second chamber where i made an aluminum fan or sorts.

Idea being that it forces a little spin to the air.

I doubt in practice it does exactly that, probably just more surface area for the oil to stick to..

Then the final chamber full of the scrubber mesh, mostly to force the air through and to give that oil somewhere to stick.

In my setup, i have my catch can mounted in the front of the engine bay, in the space where the second battery would go.

I also added a second catch can in series to see how well the first one works.

The second can never catches any oil, just water...

And that water never shows up unless it's winter/cold outside.

I'll just stick a Tornado in my catch can. It'll add filtering horsepower and MPG to the PCV system!

I actually do have one of these. Found it on the ground at LKQ. Brought it home for the novelty.

George B

¯\_(ツ)_/¯

I replaced that section with a piece of SAE 30R6 hose that was made in the USA and increased the radius. If that doesn’t do it I will hard pipe it in SS tube.I've had "meh" luck with fuel/vapor rated hoses, mostly the bulk stuff bought by-the-foot at the chain stores. Probably a source quality thing. It seems to be sure, you have to get fuel submersion rated. Kinda ridiculous for PCV, though. I like to nab factory PCV hoses off cars at the salvage yard. Cheap and guaranteed to last for 100K+ miles.

iamdub

Full Access Member

I replaced that section with a piece of SAE 30R6 hose that was made in the USA and increased the radius.

Goin all mil-spec on it.

If that doesn’t do it I will hard pipe it in SS tube.

@Just Fishing style!