You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I’m back with an Esky this time

- Thread starter Snowbound

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Snowbound

Jim

I’ve been slacking a little here lately. We had a birthday party for the wife’s best friend’s son who just turned 1. She wanted me to buy a sensory board for him. No he’s not autistic or anything, just something that’s not a stupid toy that ends up in the bottom of his toy box. The board was small and they wanted $180 for it. Yeah right, I’ll make one. Have about $80 invested and I got off work last Friday morning at 7am and by 10pm all I had left was vinyl wrap the door, mount it and put the letters across the top. Literally finished it at 12:30 Saturday, party started at 2pm. I used my kids 9.6V battery charger from an old RC car to power the lights. The board was a huge hit at the party and everyone was coming up to me complimenting me on it or asking if I could make another one. No!!

I managed to get my Firebird in the air to start cleaning and undercoating it. Plan is to get the subframe connectors welded in and start on the cage for it. It’ll be slow going as time allows.

I still need to get the front on wood blocks. Kinda sketchy on the stands.

Monday I picked up a 2010 Challenger that needed some front end work. Inner and outer tie rods and lower control arms. It has a 3.5 but it’s pretty clean. Already have a buyer lined up so it’s a nice quick flip that’ll put some extra parts money in my pocket.

As you can see from the above pic, I also put down my winter containment tarp. It has pool noodles folded in on the sides and front so when she pulls her slushy salty vehicle in during the winter it doesn’t drip and run all over my garage floor. Thing works like a charm.

I managed to get the front end done on the challenger yesterday. Just in time too, we have a snow storm coming today and forecasting snow all the way into early next week so I can’t have the wife’s vehicle sitting outside in it, she apparently thinks it’ll melt. Or she will if she has to scrape windows.

I was planning on heading north this weekend with my brother to get some much needed seat time on my sled but that got cancelled due to work obligations.

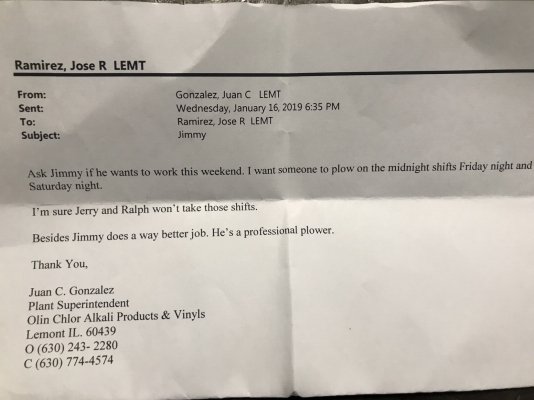

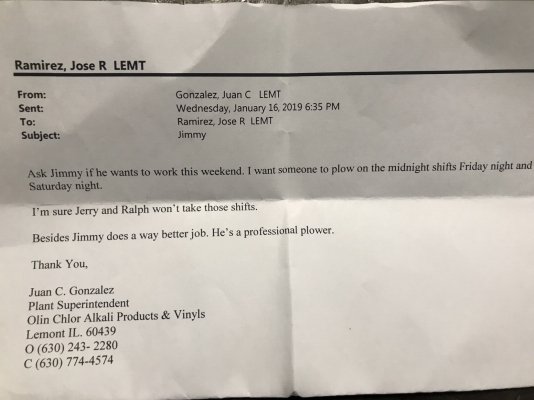

These 40 year veterans can’t seem to work a plow truck to save their life and the plant superintendent pretty much told me I had to work to keep the plant moving. I wasn’t suppose to get this email but Jose (the maintenance supervisor) is a good friend of mine and showed it to me.

And yeah, he calls me Jimmy because we had a midnight supervisor named Jim and they would always confuse us so Juan started saying jimmy and it stuck with a few guys. I hate it. Makes me feel like I’m 10.

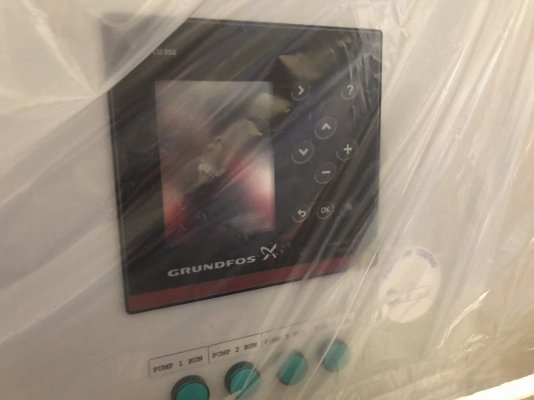

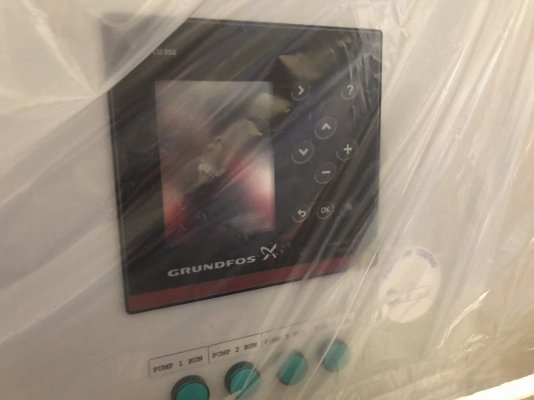

We also have to get these new raw water feed pumps installed sometime this weekend. These are replacing 2 big Durco 25hp pumps that feed raw water from quarry to the plant. These came out of Fresno CA and we are supposedly the first in the country to have a setup like this. I always like being the first, it just means we are the guinea pigs.

Another little project I did for Jose here at work. He wanted me to make a shelf for samples so the drivers wouldn’t forget them. He could have bought something but I told him I needed some 14ga sheet metal for a side project so we made a deal, he’d buy 2- 4x4 sheets of 14ga and I could keep them if I made him something for the samples. Cool. I’m game.

I did it on company time anyway so I brought in my homemade sheet metal brake and my dimple dies and formed this out of one piece of sheet metal.

I bought the wife a Cricut vinyl cutter for Xmas this year so I had her cut the letters out for me and put them on after I painted it and hung it up.

So yeah, I’ve been busy but I haven’t touched the Esky for a little while. I’ll get back at it here after the snow has stopped falling and can get a little sleep.

Sent from my iPhone using Tapatalk

I managed to get my Firebird in the air to start cleaning and undercoating it. Plan is to get the subframe connectors welded in and start on the cage for it. It’ll be slow going as time allows.

I still need to get the front on wood blocks. Kinda sketchy on the stands.

Monday I picked up a 2010 Challenger that needed some front end work. Inner and outer tie rods and lower control arms. It has a 3.5 but it’s pretty clean. Already have a buyer lined up so it’s a nice quick flip that’ll put some extra parts money in my pocket.

As you can see from the above pic, I also put down my winter containment tarp. It has pool noodles folded in on the sides and front so when she pulls her slushy salty vehicle in during the winter it doesn’t drip and run all over my garage floor. Thing works like a charm.

I managed to get the front end done on the challenger yesterday. Just in time too, we have a snow storm coming today and forecasting snow all the way into early next week so I can’t have the wife’s vehicle sitting outside in it, she apparently thinks it’ll melt. Or she will if she has to scrape windows.

I was planning on heading north this weekend with my brother to get some much needed seat time on my sled but that got cancelled due to work obligations.

These 40 year veterans can’t seem to work a plow truck to save their life and the plant superintendent pretty much told me I had to work to keep the plant moving. I wasn’t suppose to get this email but Jose (the maintenance supervisor) is a good friend of mine and showed it to me.

And yeah, he calls me Jimmy because we had a midnight supervisor named Jim and they would always confuse us so Juan started saying jimmy and it stuck with a few guys. I hate it. Makes me feel like I’m 10.

We also have to get these new raw water feed pumps installed sometime this weekend. These are replacing 2 big Durco 25hp pumps that feed raw water from quarry to the plant. These came out of Fresno CA and we are supposedly the first in the country to have a setup like this. I always like being the first, it just means we are the guinea pigs.

Another little project I did for Jose here at work. He wanted me to make a shelf for samples so the drivers wouldn’t forget them. He could have bought something but I told him I needed some 14ga sheet metal for a side project so we made a deal, he’d buy 2- 4x4 sheets of 14ga and I could keep them if I made him something for the samples. Cool. I’m game.

I did it on company time anyway so I brought in my homemade sheet metal brake and my dimple dies and formed this out of one piece of sheet metal.

I bought the wife a Cricut vinyl cutter for Xmas this year so I had her cut the letters out for me and put them on after I painted it and hung it up.

So yeah, I’ve been busy but I haven’t touched the Esky for a little while. I’ll get back at it here after the snow has stopped falling and can get a little sleep.

Sent from my iPhone using Tapatalk

Snowbound

Jim

One good thing about working midnights......

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Tonyrodz

Resident Resident

Looking good sitting there, all clean n cozy.One good thing about working midnights......

Sent from my iPhone using Tapatalk

Snowbound

Jim

When I drove this thing home from work this morning I could smell oil. She’s been telling me that she smells exhaust in the cab when she’s driving and I never smelled it. But now I did smell oil which is probably what she’s been mistaking for exhaust because it smells like engine. I know it’s because I have that breather on the catch can instead of hooked up to the vacuum source. But if you recall, I had to do that because the vacuum was sucking oil into the I take because of that PCV valve I modified for this older style valve cover. I ordered the new updated valve cover but it hasn’t even shipped yet so I cancelled it. I think this catch can is gonna solve my problem.

Anyway, I got off work and had to stop by my buddy’s house because he had a flat and couldn’t get his spare down. -21*, that’s just what I wanna be doing but I can’t leave a friend stranded. So I got his tire off, brought it home and got it filled, has a small rim leak but he’s gonna go take care of that today. Got him going and off to work and came home and tire into the Esky.

I pulled the coils and valve cover on the drivers side and I stalled the original valve cover and my ICT coil brackets.

Then I pulled off the breather and hooked up the vacuum line.

Decided to pull the cup and this is the second time I found water in there. Last week it had more than this but I’m thinking it’s because as it cools down it’s gotta be pulling moisture in. I don’t see any signs of water or moisture in oil or under valve cover when I pulled it. Strange. I’ll have to keep my eye on it.

So now it’s done and I gotta go for a ride and see if that smell is gone. I’m beat, I need sleep. Been going in at 7pm and gotta go in earlier today because we are suppose to get more snow. I sure hope this solves my issues, I need to catch a break for once.

Sent from my iPhone using Tapatalk

Anyway, I got off work and had to stop by my buddy’s house because he had a flat and couldn’t get his spare down. -21*, that’s just what I wanna be doing but I can’t leave a friend stranded. So I got his tire off, brought it home and got it filled, has a small rim leak but he’s gonna go take care of that today. Got him going and off to work and came home and tire into the Esky.

I pulled the coils and valve cover on the drivers side and I stalled the original valve cover and my ICT coil brackets.

Then I pulled off the breather and hooked up the vacuum line.

Decided to pull the cup and this is the second time I found water in there. Last week it had more than this but I’m thinking it’s because as it cools down it’s gotta be pulling moisture in. I don’t see any signs of water or moisture in oil or under valve cover when I pulled it. Strange. I’ll have to keep my eye on it.

So now it’s done and I gotta go for a ride and see if that smell is gone. I’m beat, I need sleep. Been going in at 7pm and gotta go in earlier today because we are suppose to get more snow. I sure hope this solves my issues, I need to catch a break for once.

Sent from my iPhone using Tapatalk

Snowbound

Jim

Putting original valve cover back on and hooking up the vacuum to the catch can solved the issue with the smell in the cabin. Got the thumbs up from the warden so that’s off the list. One day here soon I have to get the trunion upgrade done and I’ll probably throw in some new valve springs and seals while I’m there. I’m going to be swapping the cam when I do the exhaust. I think I want to pull the heads so I can do new lifters and it’ll make extracting broken exhaust manifold bolts a little easier. To be continued, like everything else I drive, I’m never done until it’s wrecked or sold.

I gotta throw a picture up here so here you go.

Sent from my iPhone using Tapatalk

I gotta throw a picture up here so here you go.

Sent from my iPhone using Tapatalk

Snowbound

Jim

Leaning towards these KMC 707 wheels in a 24”. I can’t make up my mind so I’m gonna go and set them next to the vehicle.

Picture off their site on vehicle.

Tried getting a pic of it lowered with them wheels but could only get it in an ESV but I think it’s gonna be the best compromise between the old lady and I.

Sent from my iPhone using Tapatalk

Picture off their site on vehicle.

Tried getting a pic of it lowered with them wheels but could only get it in an ESV but I think it’s gonna be the best compromise between the old lady and I.

Sent from my iPhone using Tapatalk

how are you liking those mevotech control arms? any issue's?

petethepug

Michael

Good move on getting into the susp after 100k. Just had our rack, inner & outer tie rods changed @ 136k on our 08 XL Denali. It took a lot of play out. On the straight aways I no longer have to correct the steering wheel every 3-5 seconds.

Did the new front end parts cure any cold weather related suspension squeaks? Below 40 some of our front end bushings get noisy over speed bumps until the truck warms up.

Sent from my iPhone using Tapatalk

Did the new front end parts cure any cold weather related suspension squeaks? Below 40 some of our front end bushings get noisy over speed bumps until the truck warms up.

Sent from my iPhone using Tapatalk

Similar threads

- Replies

- 11

- Views

- 760

- Replies

- 22

- Views

- 3K

- Replies

- 15

- Views

- 925

- Replies

- 11

- Views

- 1K