And with the new converter, i used a cheap amazon fluid transfer pump that I purchased last year to suck most of the fluid out.

Afer reading through the reviews mentioning how hot this thing gets, i cracked open the case for a good look.

no fans, just some tiny holes.

so i opened each of those up on the front, and then added a few on the bottom and the top to help flow heat out of the case.

that helped a ton, but i still run it with a fan blowing on it.

It works great that way.

I modified the suction end to add some cheap 6mm air line that i have for some amazon special pneumatic cylinders.

Used heat shrink tubing to seal up the end for the extension.

I also took this apart when i first got it, mostly to see how it functioned.

if it looked like a plastic pos then i would have just returned it and got something better.

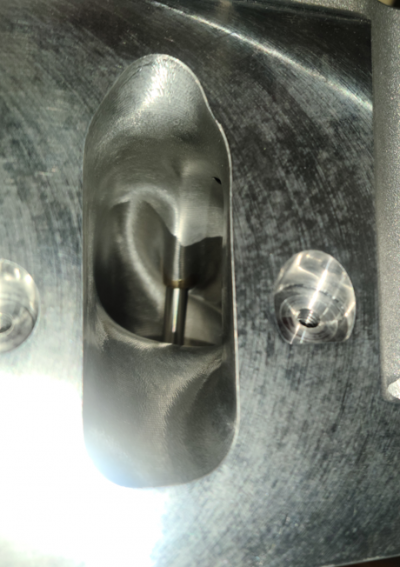

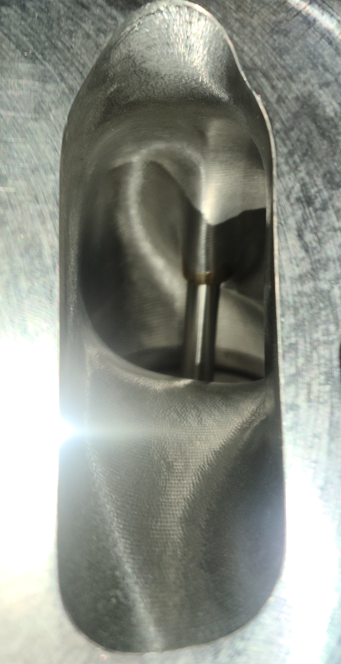

but inside i found a pump that loosely looked like a transmission pump, or an air tool.

Cast metal outside, and copper veins.

the veins looked like pretty solid copper when compared with some 99.9% copper pipe i have laying around.

I smoothed the ends up while i had it open with a fine file, and gave the little veins some cross hatching to help them seat and seal a little better.

It seemed to have a hard time self priming + you really want to keep that thing lubed up.

especially with the hose extension i installed.

So i found i can prime it pretty easily by disconnecting the inlet hose, and then using my brake fluid suction tool to prime the line.

Attach to the pump and turn it on!

for the battery, i just use a spare lawn tractor battery that i have sitting around.

while it's slow, it does work.

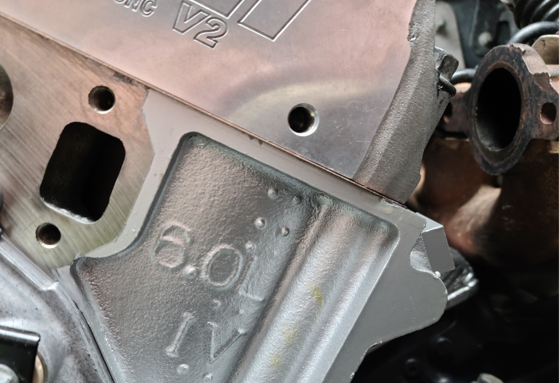

SO last night i yanked the pan, easy to get to while the exhaust is hanging...

And installed a brand new acdelco filter after cleaning up the pan.

The gasket on the 6l80's are reusable, I love that.

I still have a spare laying around, but no reason to replace it since i already did about a year ago.

Next step for today, lower the truck down onto some shorter jack stands.

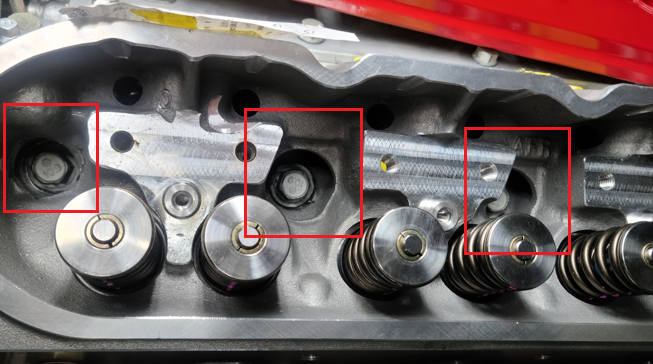

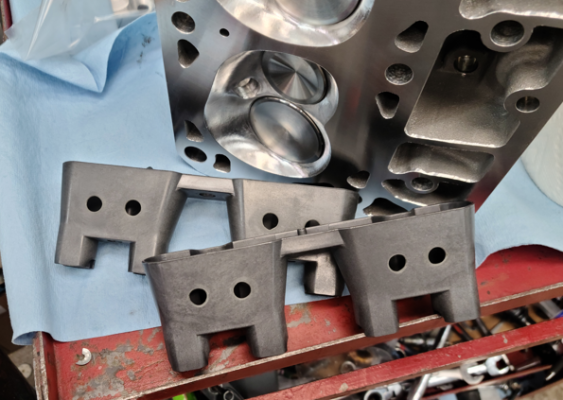

From there i do some valve clearance checks with my lump of clay

Clay I'm using:

https://www.amazon.com/gp/product/B00FR7TTNA

I picked up a return that had a torn package for about $4

When i checked before, i tossed in a good inch thick chunk of clay and gave the engine a good turn with the .030 gasket shim and had no contact.

I don't expect to see any difference, but it's better safe than sorry!

From there, i get to start installing cylinder heads!!

Then i get to double check my pushrod length with the ol dial indicator.

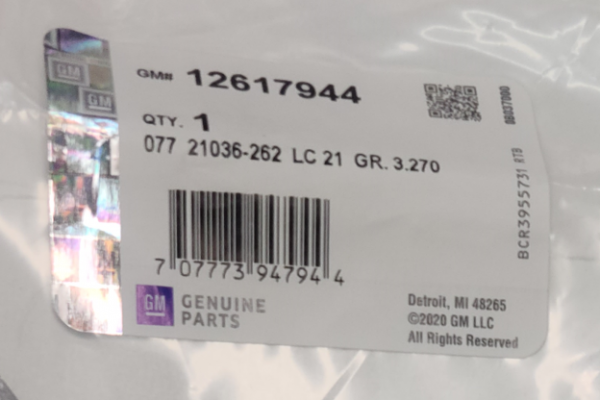

I'm also planning to order these,

COMP Cams Ultra Pro Magnum Rocker Arms 1.8 ratio

https://www.summitracing.com/parts/cca-1677-16

Going for the higher ratio comes from two ideas in my head.

First these heads support something like .650 lift.

And as i Understand it (or if i understand correctly)

The higher ratio also affects duration slightly, that in turn lowers the DCR just a little.

If it makes enough of a difference?

There is also a 1.82 ratio set for the aluminum gold line, but that's an extra $150.

and that's $150 i could use towards an upgrade my hp tuners for logging and wideband.

If anyone has any pointers on how to adjust fueling using hp tuners, i'm all ears!

Otherwise, it looks like a wideband is the best option.

but i need to figure out where to put the extra bung.

The damn cats are so far forward on this thing, and i know i need to get a read before the cats...

And No not this kind of cat