Been thinking about that, but i heard that octane boost didn't really work.

doing some thinking about the subject, and the fact that i have some pretty lame timing from an 08 2500 hd silverado 6.0, I ran with that.

Really spark knock should only be a thing under load, so i decided to go with it.

I opted to do some data logging with hp tuners during the startup cycle.

looking for knock and knock retard.

I also watched the fuel trims to see how far it was off.

so far it seemed to be removing more fuel than adding.

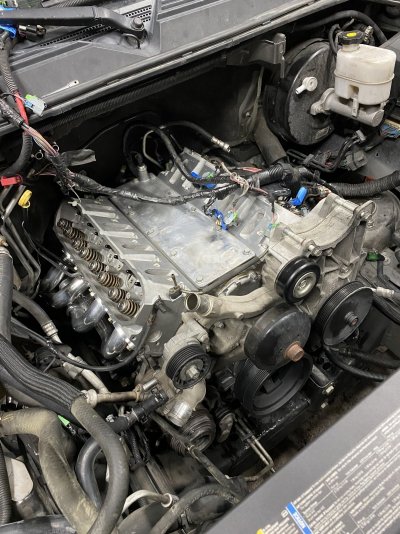

Engine is alive!

I found that i totally forgot to connect the power lead to the alternator after i spent some time trying to figure where the fk i put i.

then i remembered, it should go directly to the battery!

Found it spooled up next to the battery, just where i put it back in march.

Then I totally spaced it and routed that pig back in place with the battery hooked up.

nothing important shorted, but it did manage to let me know as i routed near the alternator for a split zap.

(Making a note of this little whoops as i try and figure out the wtf at the bottom of this post)

(Making a note of this little whoops as i try and figure out the wtf at the bottom of this post)

So I started up the engine, and it was not happy at all.

I thought it was the throttle/idle learn bs so i chased that goose for a bit.

then i started reading up on the error being with the tps sensor.

Then i found it totally disconnected.

Routing that alt power wire I disconnected the throttle position sensor.

And apparently I totally forgot to plug it back in... lol

First break-in cycle ran through, i did maybe 10/20min of 1500 - 3500 rpm slow up and down.

No knocks noted in hp tuners.

Hard to keep track of time as i was chasing my tail with the sensor, and the transmission fluid level.

I ran it longer than i would have liked to with the transmission fluid low.

like a gallon low...

Maybe a 30sec +/-

From there I kept up on the fluid with the engine off, knowing it should sit above the full/hot level with out the pump running.

+I read to not let the engine idle during the first bit of the run time.

Then did an oil change, and filled up with one more go of break-in oil and a fresh filter.

Lots of magnets on those filters.

Then took the hoe for a nice little drive while logging for spark knock.

I noticed a few here and there, but nothing major.

I went to the gas station that had the race fuel @ 110 octane, but none was found.

So i topped off with some 91.

My thought was to do lots of low speed cruising with stops and goes.

kept it in tow mode to ensure i got some decel engine braking for those rings.

the 6.0 has a noticeable increase of low-end grunt, even with me just going easy on it.

Me like very much.

but then i ran into an issue.

Mid throttle/ish, is started to get a reduced power message and the hoe would start to run like ass.

Super rich.

rich is bad, especially during the break-in cycle.

it rinses my bore and rings from the expensive break-in helpers.

Code: p0606

That comes up as a generic ecm fault.

so either something went funky with my tune, I missed a ground, or i shorted something out.

When installing the engine, we did manage to lightly crush some of the wiring that routes above the intake.

I did some mild cleanup and taping, i didn't find anything broken.

Just some damaged insulators

wrapped those damaged wires with some super 88 and called it gtg.

( I'm making a note of that as i might need to do more checking of that wiring harness later)

I also got a pretty solid air bag warning message, I remembered the guy that helped me get the engine installed pointed out that he damaged a sensor.

That's the first place i'll start, maybe I have a short.

Last night i also took a crossbuff that fit the battery terminal and cleaned/polished that pig to perfection.

On a positive note, my pushrod length so far seems to be good.

One step below 7.4 seemed to be about right with the original heads, and that seems to have carried over with the afr heads.

Today my task is to clean up the garage a little, and add some refrigerant to the hoe, and then start checking things.

if the error keeps up, i'll try a different tune.

But i'll probably try writing the current tune once more for good measure...

Either way, i need AC if i'm going to spend any time in the hoe.