I got everything reconnected that is needed to fire her up, and added all the necessary fluids this past weekend. Reconnected the battery and...................... no start, no crank.

Dropped the battery off at Autozone to have them test and charge it. Dropped it back in, and still no start, no crank. I'm thinking its some sort of communications issue with the computer. I'll start a separate thread to discuss the diagnosis of this issue to not clutter this thread up.

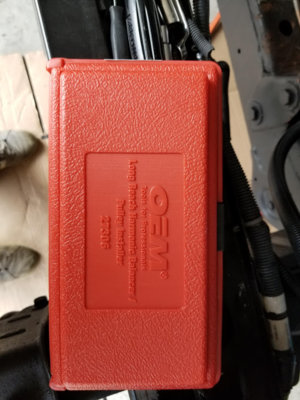

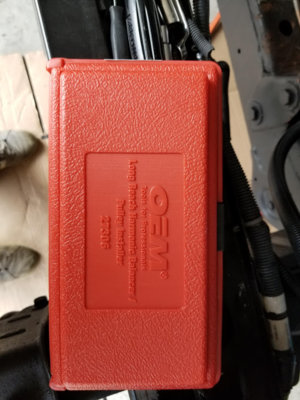

Stepping back to the final steps or getting things buttoned up. I used the free loaner tools from Autozone to install the crank pulley. The "Long Reach Harmonic Balancer Installer" #27306 works great for getting the pulley most of the way on, then I used the old bolt, and the Autozone loaner torque wrench to torque it down to 240ft/lbs. My own torque wrench only does a 150ft/lbs, so it was nice not needing to buy a much more expensive torque wrench for just one bolt. I then remove the old bolt and installed the new one to 47ft/lbs plus 140 degrees (I think that is right, going off memory).

Finishing things off, I reinstall the coolers on the front end, install new accessory belts, new starter, and finish connecting the hoses and wiring. To de-cluter the engine bay a little, and make fun sounds I install an Airaid intake tube, with a K&N filter in stock air box. The fitment on the Airaid is great and its super simple to install. I'm happy I went this route over a full K&N intake. Its simple, clean, and I believe one of the cheapest options.

Now if I could just get the dang thing to do something besides flash a few lights on the dash.......

Here's the thread I started to help diagnose the no start. Your help is appreciated.

https://www.tahoeyukonforum.com/thr...e-now-no-cranck-no-start.107442/#post-1281092

Dropped the battery off at Autozone to have them test and charge it. Dropped it back in, and still no start, no crank. I'm thinking its some sort of communications issue with the computer. I'll start a separate thread to discuss the diagnosis of this issue to not clutter this thread up.

Dropped the battery off at Autozone to have them test and charge it. Dropped it back in, and still no start, no crank. I'm thinking its some sort of communications issue with the computer. I'll start a separate thread to discuss the diagnosis of this issue to not clutter this thread up.