The move to thinner oil viscosity was not for the engines protection or longivity. See info below from Pennzoil FAQ section of their web page.

Start with a thin oil, add gasoline, then you have even thinner oil. Add enough gasoline and you are lubricating with a solvent. All bearing surfaces are supposed to run on a film of oil, when the oil has too low of a viscosity the oil film and oil wedge collapse and then you start to have no film to support the parts and metal to metal contact can begin. Dilute the engine oil with fuel and it will not stay on the bearing surfaces and journals as well once the engine is shut down.

Once the oil thins out, the oil pressure will likely decrease as well, adding to the overall oiling problem. Then the oil consumption really starts to skyrocket, this is another problem with engines cronically run low on oil. Then the oil contamination starts to run away as you have less oil to support the amount of fuel being added in the oil.

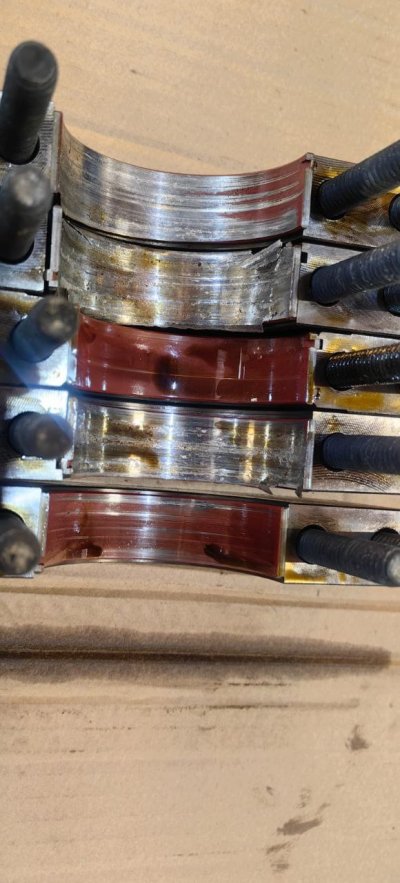

I think it is pretty clear from Vladimirs post than different bearings still fail. It appears the pictures show main signifigant main bearing wear, which will lead to rod bearing wear because the rod bearings are lubribrated from the main bearing oil supply. If the engines are opened up, inspected and reassembled with different parts and they are still failing from what appears to be oil related failures, what do you thing the problem may be? Is it possibly related to oil, lack or oil and/or fuel diluted oil?

There is also cam lobe that failed as well in one of Validimir pictures, not sure it was from the same engine. From the looks of the pattern on the cam lobe, the lifter did not spin in the plastic holder, the needle bearings in the lifter likely failed. A failed cam lobe while putting metal in the crankcase, should not cause the level of bearing failure because the oil filter will catch most particles large enough to damage the bearings. While fine metal particles circulating in the oil is not a good thing, bearings have the abilitiy to allow smaller partcles to embed in the material and should protect the harder journal surfaces.

Keep in mind the roller lifter bearings are also under a lot of stress due to their size and lobe ramp shape. There are tiny needle bearings inside these lifters that need a decent oil film to operate on. While some of the lifter failures are due to lifters spinning in the plastic stabilizers, some are failed roller bearings likely due to oil viscosity break down due to fuel contamination.

The short answer is I would not run 0W20 or thinner engine oil in any modern engine, bottom line it is just way too risky and for most people they will not see 200,000+ miles on engines running 0W8, 0W16, 0W20 oils, espeically in DI engines that suffer from a higher amount of fuel contamination.

All this talk about faster oil flow on start up is a double edged sword. The thinner the oil, the more likely it is to leave a thinner film of oil on journal and bearing surface when the engine is turned off, especially since the engines are usually hot when shut down. Seems that all of these engines failures occur while driving and many are actally siezing. Most sieze without prior warning or noise or without my notice. Seems to me that this screams more oil starvation/oil film break down then dry start up accelerated wear. Especially when the many of these engines are failing are relatively low mileage.

If you are lucky, your 5W30 or 0W40 engine oil will still have a similar viscosity index at 5000-7500 miles as the fresh 0W20 engine oil that had 0 miles.

Thin oil is being used for fuel economy and emissions due to "legislated regulations"!

Directly from the Pennzoil web site FAQ area -

https://www.pennzoil.com/en_us/education/know-your-oil/0w-viscosity-faqs.html

Within the past decade, original equipment manufacturers (OEMs) have been tasked to meet the legislated regulations for better fuel economy. OEMs have made huge strides by reducing engine size and maintaining horsepower performance through the introduction of smaller Turbocharged Gasoline Direct Injection engines (TGDI) and operating on thinner viscosity grades.

The push for SAE 0W-20 and SAE 0W-16 motor oils grades has helped OEMs achieve some of those fuel economy and emission targets.

Pennzoil Platinum SAE 0W-16 and SAE 0W-20 meet and exceed the need of these engine oil specifications. It is designed to meet these fuel economy benefits while offering outstanding performance and protection throughout the oil drain interval.

The benefits of using the correct 0W grade oil for your vehicle are faster flow at start-up to reach critical engine parts, faster engine warm up and delivers better fuel economy as compared to higher viscosity grade oils.