I don't think it was bent it was just not balanced with the new u-joints and 160k on itout of round? like they bend the thing? wow.

that's cool they could fix it. hopefully all good. back when I dealt with it. they just spun it and tack welded washers on them haha. sounds like your shop is much better

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your NNBS GMT900 Tahoe/Yukon Today?

- Thread starter phattyford

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

got one of my offspring to lend a hand and re-installed it, couldn't get a socket and wobbler on there to get to 18ft lbs so I gave it a couple ugga-ugga's and called it good.

took it up to around 128 and without doing a concise before and after from before it was worked on I will call it 98% and good to go. They did weld a washer looking piece on it and then painted it so I don't know what else they did besides heat treating it. they were busy and I just wanted to get this back in and road tested.

~~vacay on schedule~~ unless something else outside of my control happens

View attachment 403396

128 you'd definitely feel anything big. take awesome they could get it usable. I honestly thought you were going to have to toss it. glad I was wrong incase I ever do mine. mine never goes over maybe 90 lol.

side note, I was watching airplane stuff and you can tq with a crows foot on a torque wrench. you just gotta keep it at a 90deg right angle and it's the same as at the socket. straight out its less, but there's some math for it if need be, and 180deg back ups the tq.

I don't know if you can it in there, an I'm sure it's fine. just read that a few months ago about torquing an fittings.

ya I didn't think about that I have a set of them in another tool box, I should be fine until next time I get under it or I usually do a vehicle check while I am traveling anyway when I get up the coast I will check them to make sure nothing has worked it's way loose but I tend to over tighten so they are probably over 18lbs128 you'd definitely feel anything big. take awesome they could get it usable. I honestly thought you were going to have to toss it. glad I was wrong incase I ever do mine. mine never goes over maybe 90 lol.

side note, I was watching airplane stuff and you can tq with a crows foot on a torque wrench. you just gotta keep it at a 90deg right angle and it's the same as at the socket. straight out its less, but there's some math for it if need be, and 180deg back ups the tq.

I don't know if you can it in there, an I'm sure it's fine. just read that a few months ago about torquing an fittings.

used some auto parts store 75-90 that of course had limited slip additive in it cause they all seem to these days and I didn't think much about it at the time. that was about 10k miles ago, today the wife calls and says the rear end is making a funny noise when I made a u turn and feels like when we used to have to push cars with a welded diff afterwards for a few turns in the parking lot.

so yeah grabbed some fluid from the dealer on the on way home since I've read these g80s sometimes chatter with off the shelf oil. blah. we shall see if it does it in this stuff or if it was the oil.

here's the latest part number according to my local guy, replacing 89021677. dealer wants 35$ for it, 17$ on Amazon. I got them down to 25$.

while under looking around, you guys ever hear of the rear heater hose quick connects breaking? cause mine look pretty horrible and it looks like there's not a split, they run all the way to the front? ugh.

oh and I have a 4in aluminum drive shaft, don't know where gm meausues from, but tip of ear to ear is 41in.. I guess it's stock? don't know if it's would fit anything else but these odd ball trucks.

so yeah grabbed some fluid from the dealer on the on way home since I've read these g80s sometimes chatter with off the shelf oil. blah. we shall see if it does it in this stuff or if it was the oil.

here's the latest part number according to my local guy, replacing 89021677. dealer wants 35$ for it, 17$ on Amazon. I got them down to 25$.

while under looking around, you guys ever hear of the rear heater hose quick connects breaking? cause mine look pretty horrible and it looks like there's not a split, they run all the way to the front? ugh.

oh and I have a 4in aluminum drive shaft, don't know where gm meausues from, but tip of ear to ear is 41in.. I guess it's stock? don't know if it's would fit anything else but these odd ball trucks.

Attachments

@Rocket Man i think has some input on those rear heater connectionsused some auto parts store 75-90 that of course had limited slip additive in it cause they all seem to these days and I didn't think much about it at the time. that was about 10k miles ago, today the wife calls and says the rear end is making a funny noise when I made a u turn and feels like when we used to have to push cars with a welded diff afterwards for a few turns in the parking lot.

so yeah grabbed some fluid from the dealer on the on way home since I've read these g80s sometimes chatter with off the shelf oil. blah. we shall see if it does it in this stuff or if it was the oil.

here's the latest part number according to my local guy, replacing 89021677. dealer wants 35$ for it, 17$ on Amazon. I got them down to 25$.

View attachment 403432

while under looking around, you guys ever hear of the rear heater hose quick connects breaking? cause mine look pretty horrible and it looks like there's not a split, they run all the way to the front? ugh.

View attachment 403434

oh and I have a 4in aluminum drive shaft, don't know where gm meausues from, but tip of ear to ear is 41in.. I guess it's stock? don't know if it's would fit anything else but these odd ball trucks.

View attachment 403436

@Rocket Man i think has some input on those rear heater connections

I was honestly wonder if I can just cut the pipe, flare it some and stick some fresh heater hose over it and clamp.

but I also can't say I've ever seen a thread about them leaking and I hate to fix things till they are broken haha.

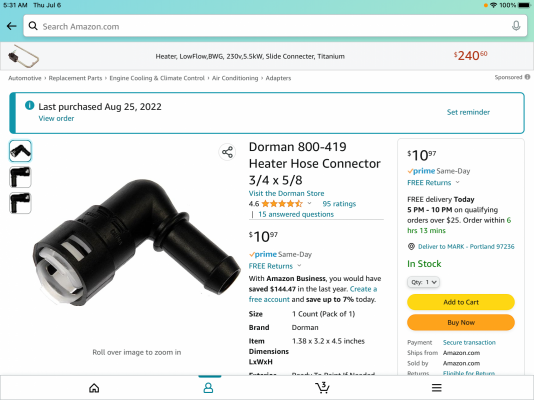

If you mess with them, you’ll need right angle quick connects because there’s no room for the heater hose to make the turn from vertical to horizontal if you don’t. I used some Dorman ones because that’s all I could find. Mine were brittle as hell after 21 years, no way they were coming off in one piece. I cut them off with tin snips.Not sure why they weren’t leaking but I recommend replacing them if they’re old. Dorman 800-419 is the part number. The hose will need a couple clamps.I used spring clamps I had laying around.I was honestly wonder if I can just cut the pipe, flare it some and stick some fresh heater hose over it and clamp.

but I also can't say I've ever seen a thread about them leaking and I hate to fix things till they are broken haha.

Attachments

alpha_omega

Full Access Member

Those are really nice. How many miles can you go between fuel stops?

They didn’t install the driveshaft upside down after they replaced the joints did they? Best procedure is to balance the shaft, but if you are doing it yourself you can just mark the relationship of the shaft prior to removal.went and picked up the yukon from the dealer after having the rear u joints and fuel pump done and mf'r is vibrating like a sob.

called them and they said they do not balance the shafts and would have to send it out, so 1st thing Monday i'm going to run it down to the driveline shop

and tell them I need a rush on it already paid for a bunch of stuff for the vacay no time to screw around.

apparently they do not have a QC guy on Saturdays and it was closing time so limped it home even though I didn't want to vibrations f-up the ring & pinion.

Could be something as simple as Amateur Hour at the stealership and **** the new guy might have skipped that step.

alpha_omega

Full Access Member

What the actual f*¢k? And this is the reason why I do all of my own work. Negligence and embarrassing attention to detail.No other mark, but there is a fresh scratch mark corresponding on the other side but I think I found the problem or part of the problem WTF!

View attachment 403098

A while back I purchased a u-joint puller/installer tool from tiger tool. There are others out there, but they are not as well built. A friend of mine cheaped out and after it’s second use he snapped the arm off the lesser quality that one he bought.

Automotive U-Joint Puller

The original. The one and only Tiger Tool U-Joint Puller designed to last and out-perform anything else on the market. Provides ultimate brute strength for disassembling even the most seized u-joints in minutes.

tigertool.com

tigertool.com

Similar threads

- Replies

- 3

- Views

- 3K

- Replies

- 56

- Views

- 8K

- Replies

- 35

- Views

- 12K