Honestly, this is all stuff that can probably wait until you have an event that makes doing the work necessary anyway, which may never happen. The odds are in your favor. There are plenty of people running around with 300K+ on their original cam phaser and timing components. And since you have the AFM tuned out, your odds are better than most that such an event won't happen during your ownership.OK, I am getting cold feet.

I have read through various procedures in the service manual, and this is becoming a steeper and steeper slippery slope.

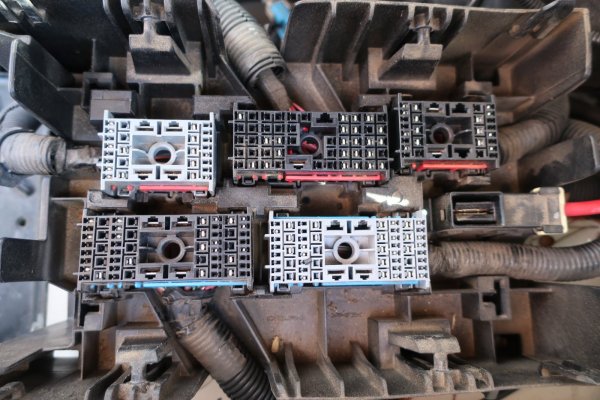

To replace the VVT actuator (camshaft sprocket):

-lower front differential

-remove oil pan

-remove timing cover

-remove oil pump

-remove timing chain tensioner

-remove VVT actuator and timing chain

And this is on the edge of the cliff of:

Since you was in there...

AMF Delete

-'Just Pop the heads off to replace the lifters.'

-pull the radiator

-pull the AC condenser

-pull the auxiliary transmission cooler

-replace camshaft

To be honest, that is WAY more money and time than I want to do right now.

The scope of what I am doing now was some preventive maintenance. My intent was only to have my Escalade down for a couple-three weeks.

All the above will add considerably more time to this.

The main reason I did my cam swap was because I only had 110K on the thing and wanted to tow a heavy camper with it, so my main goal was more power, with increased durability as a secondary gain.

)

)