You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Camaro SS, track trips, build pics etc.

- Thread starter 01ssreda4

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

iamdub

Full Access Member

I vote red for the tubing to have the continuity from the original frame. But then black or silver would contrast and say "I'm custom". Hmmm...

Any numbers on net weight savings?

Any numbers on net weight savings?

Not sure, I already hauled the front frame off to scrap and didnt weigh it. Based on my bicep meter i estimate it to weigh 50 pounds (mine was trimmed and will be lighter then stock). Ive also seen someone else say they weighed it to be around there (65) also. New metal I figure all said and done i will add 15ish back on. So total savings "should" be in the 45-50 pound range.

This first pic is off RSMs facebook page. I thought some would find it useful.

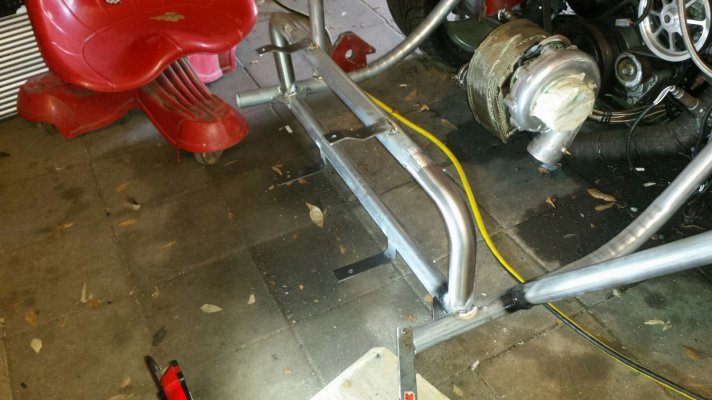

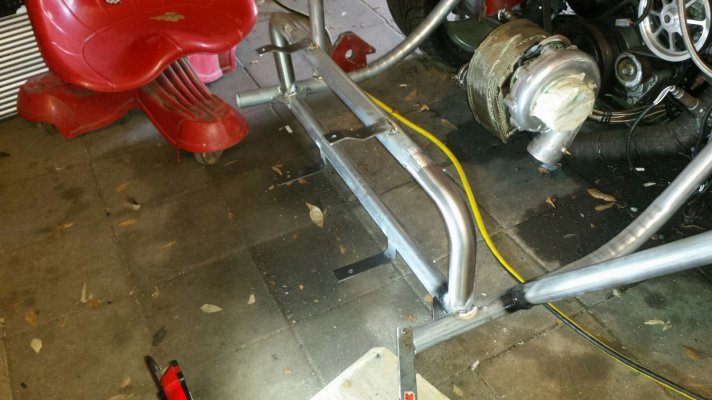

Got the main hoop made and some simple flat bar brackets welded on to hold the intercooler. The 90 degree bends here are stainless and were found on ebay for 20 bucks. No way I could have made a bend that nice so I decided it was ok to buy/use these.

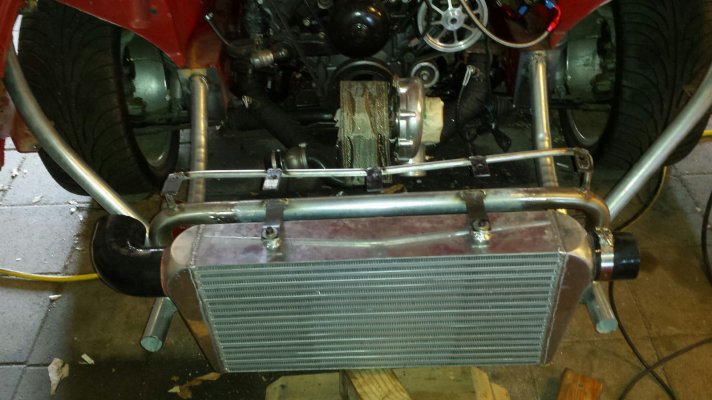

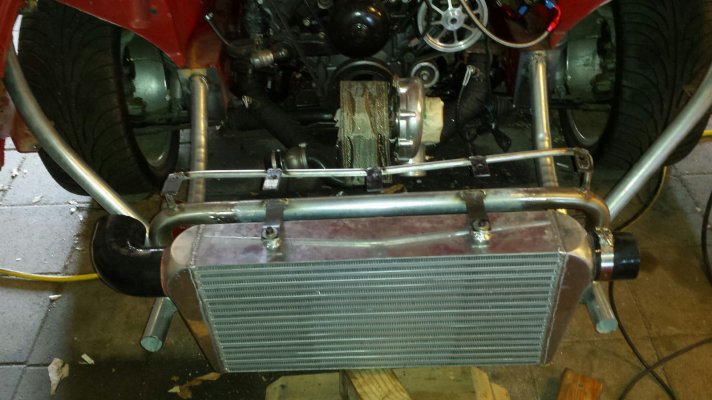

The intercooler has been flipped where the outlets are up top. With 90 degree elbows they just clear the main hoop, and are just under the headlights. I also made an extension on the main hoop to hold 5 tabs that support the bumper and have holes for the pushpins.

Hood latches, and the biggest tap Ive ever owned.

I cringed a little drilling through the hood. Not a lot but a little.

Some simple square tube and flat bar brackets for the hood latches. This was the first attempt. I realized the angle needed altered. These are welded on the main hoop.

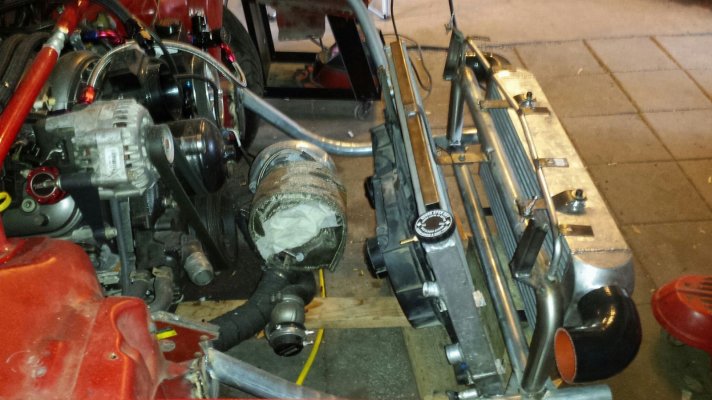

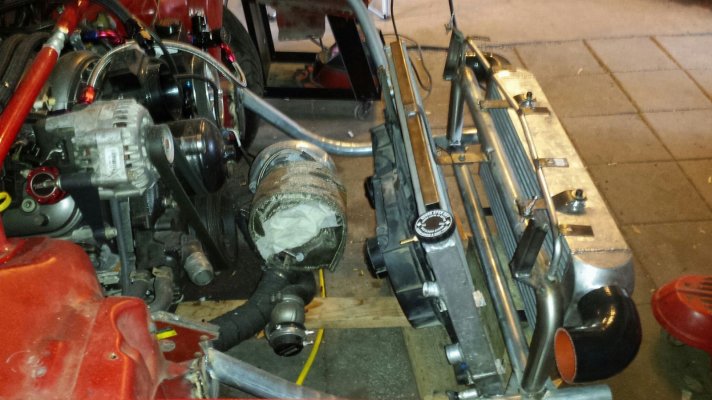

Homemade lower radiator support. I am using the passenger side rubber donut but otherwise the radiator will be sitting on the square tubing. The metal on the top and bottom of the radiator is fairly thick and by distributing the load over the entire area should not have any rubbing issues.

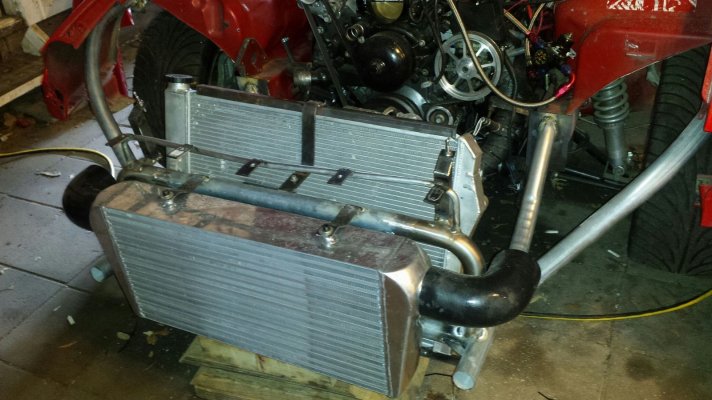

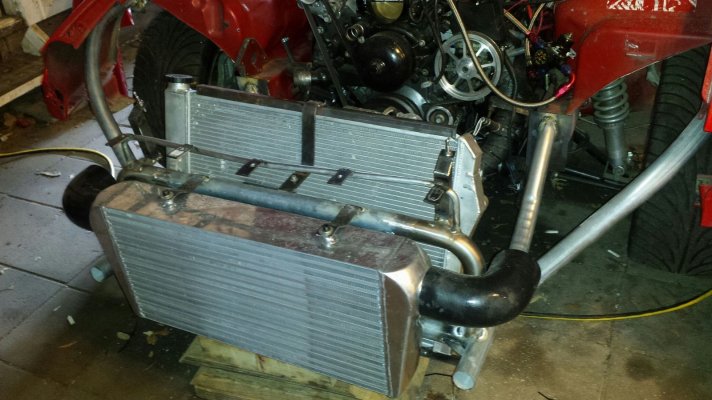

Here's the radiator sitting on the lower support. Im keeping it as close to straight up as possible for turbo clearance. Here I'm checking hood clearance. Zip ties are your "little helper".

Upper radiator bracket made and fans mounted and back on the rear as they were stock. One bolt and the entire radiator comes out, yeeeah. Again, square tube up top and across to distribute load.

Another look.

And Im done for the weekend. This is way more work then I originally thought. I "hope" my next update will be a road trip and a roll cage on a trailer. We shall see.

Got the main hoop made and some simple flat bar brackets welded on to hold the intercooler. The 90 degree bends here are stainless and were found on ebay for 20 bucks. No way I could have made a bend that nice so I decided it was ok to buy/use these.

The intercooler has been flipped where the outlets are up top. With 90 degree elbows they just clear the main hoop, and are just under the headlights. I also made an extension on the main hoop to hold 5 tabs that support the bumper and have holes for the pushpins.

Hood latches, and the biggest tap Ive ever owned.

I cringed a little drilling through the hood. Not a lot but a little.

Some simple square tube and flat bar brackets for the hood latches. This was the first attempt. I realized the angle needed altered. These are welded on the main hoop.

Homemade lower radiator support. I am using the passenger side rubber donut but otherwise the radiator will be sitting on the square tubing. The metal on the top and bottom of the radiator is fairly thick and by distributing the load over the entire area should not have any rubbing issues.

Here's the radiator sitting on the lower support. Im keeping it as close to straight up as possible for turbo clearance. Here I'm checking hood clearance. Zip ties are your "little helper".

Upper radiator bracket made and fans mounted and back on the rear as they were stock. One bolt and the entire radiator comes out, yeeeah. Again, square tube up top and across to distribute load.

Another look.

And Im done for the weekend. This is way more work then I originally thought. I "hope" my next update will be a road trip and a roll cage on a trailer. We shall see.

iamdub

Full Access Member

Diggin the fab work!

Bicycle inner tubes are a cheap and easy insulator for between the rad and support. I know it's a race car, but I also know it doesn't idle like an LS400. Then there's the whole possibility of galvanic corrosion between the dissimilar metals.

Bicycle inner tubes are a cheap and easy insulator for between the rad and support. I know it's a race car, but I also know it doesn't idle like an LS400. Then there's the whole possibility of galvanic corrosion between the dissimilar metals.

100% agree, the lack of padding has been on my mind. I believe both surfaces will be painted, and if things keep going as they have been, and about 100 miles a year being put on the car, I think it will be fine. The inner tube is a clever idea. I just may use that or something similar.

iamdub

Full Access Member

100% agree, the lack of padding has been on my mind. I believe both surfaces will be painted, and if things keep going as they have been, and about 100 miles a year being put on the car, I think it will be fine. The inner tube is a clever idea. I just may use that or something similar.

I used some inner tubes between a fuel tank and it's straps. For a radiator setup, I'd go with something like this from Home Depot: https://www.homedepot.com/p/M-D-Bui...-Auto-and-Marine-Weatherstrip-01033/100175299.

It's a bit higher caliber than the inner tube idea so it's better-suited for your build. It would absorb the vibes much better than in inner tube to prevent cracking the rad.

PoPoPPV

Full Access Member

Rippin' thru it! There's nothing like doing the work yourself, even when its the 1st time you've attempted something, crazy satisfying feeling!!

Quick update: Hood safety release handle is reinstalled, fenders/bumper are braced, headlight mounts are done, catch can and radiator over flow have mounts. Everything was test fit before disassembly. Radiator and fans have been cleaned and painted. I tried out some Rustoleum brush on paint. I may go back and do this red, haven't decided. I got the call, roll cage and wheel tubs pick up on Tuesday.......so that means, road trip finally!!

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 6

- Views

- 1K