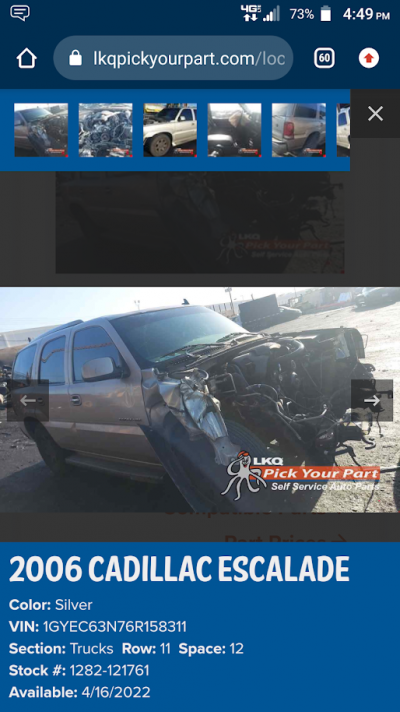

Recently, I picked up another big beefy piece of the puzzle for the Tahoe transformation, a 14B SF "AXN" rear axle from a crashed 06 Escalade 2wd that showed up locally. My original 10B rear axle is functional and quiet, but I figured why not...with the 6.0 swap and the factory spec-ing this axle for 2wd 6.0 applications, which my Tahoe is 98% of the time, except those rare times that I hit the 4wd button. Thankfully these axles only came in 3.73 gear ratio, which matches the Tahoe. Also managed to score the gauge cluster from the same Escalade and it shows ~180k miles. I popped the rear cover to have a look and check the magnet with that mileage, but everything looked really good inside. No limited-slop-gov-lock-bomb but that's okay.

Hopefully it's a straight bolt-in but that will be figured out once the engine is complete and the trans gets done. I didn't get the track bar, as they visually looked the same between the Tahoe and Escalade. Driveshaft I didn't bother with since the length was wrong, 2wd v 4wd. One minor difference I've already spotted is the drop down brake line difference. The Escalade axle has separate lines for each side and the Tahoe has a single drop line that splits side to side on the axle....shouldn't be too much of a hurdle though.

The only drivetrain piece that will be untouched is the transfer case. But that brings up a question, does the 1500 transfer case in an 04 Tahoe Z71 suffer from the same problem I've read about in the 2500HD transfer case....aka "pump rub?" If it does, how can it be checked for? Is there a thread with detailed info in the 1500 T-case?

View attachment 370843View attachment 370844