blueinkd

Full Access Member

- Joined

- Nov 21, 2017

- Posts

- 633

- Reaction score

- 1,511

Shortblock is out and should be at machine shop Monday morning. No pics as it got late when we finished and needed to clean up.

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Lil’ help? Power wire 8AWG thru Firewall Grommet.

Audio head unit + backup camera install is complete. Speaker and subwoofer is complete. Amp is mostly complete but I’ve hit a barrier.

I was not able to get 8AWG amplifier power wire through the firewall main grommet. Made a small incision in the upper engine side boot. Used Klein wire lube. Fished and poked around for about 40 mins but didn’t make any progress. This will be a really clean install when complete. OCD’s (you know who you are…) don’t hate on me! I offset the amp to pax side (right) to give more clearance for wires and avoid the groove in the console mounting plate. Form follows function. Now I just need power.

Anybody got tips on how to get thru the firewall?

Also, grounded with an 8AWG to floorboard but added a supplemental ground to the seat and console mount plate, which I believe is grounded / connected to the frame.

I sanded paint down to bright metal under the supplemental ground , but can anybody confirm if this will work? @iamdub, will this work?

Thanks in advance.

Your power wire grommet is artwork.

I’ll drill thru the floor near the rear mount of the front seat, Near my ground.Oh-See-Dee, yo! Thanks.

You make me want to Build my own ground straps!!! Im assuming you are making those in house??I think that one you were trying with is dual-layered. I don't bother messing with the factory grommets. It's just not worth the hassle or risk of nicking a wire or causing a leak. Bring a piece of your power wire to an auto parts store or hardware store (Home Depot, Lowe's, etc.) and look for a grommet like this:

View attachment 399938

You want one that fits firmly on the jacket of your power wire. Here's mine where I ran it through the floorboard, near one of the right rear seat mounts:

View attachment 399939

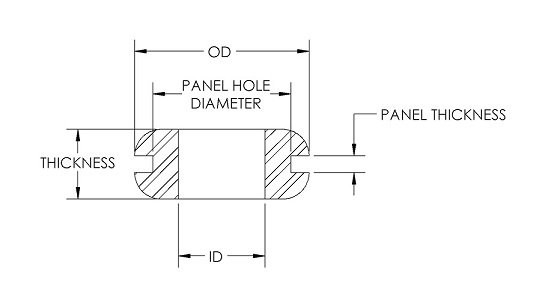

I drilled the hole to the OD of the recess in the grommet ("PANEL HOLE DIAMETER" in the following image), cleaned the drilling burrs from around the edge of the hole then painted the metal and let it fully dry. The wire needed a little spritz of lubricant ever so often to slide through the grommet cuz it was a firm fit. Which, is what you want for proper sealing.

View attachment 399947

"OCD" you say?

View attachment 399940

View attachment 399941

Not directly. The seats are bolted to the cab floor, to sheet metal. A circuit needs to have the same ampacity throughout all of its conductors. Otherwise, the ampacity of the smallest (weakest) point will be the circuit's maximum. The battery is grounded to the frame. The body (sheet metal) is grounded to the frame with some rather electrically weak cables. You can ground that amp to sheet metal or to seat frames, etc. that are bolted to the same sheet metal, but that sheet metal needs a matching ground to the frame. So, you'd need an 8 gauge ground from the body's sheet metal to the frame or engine block. I have a 4 gauge ground from the body to the engine block, which is grounded to the frame with 1/0. It's actually the original factory main ground that went from the battery to the engine block, just relocated to the sheet metal:

View attachment 399942

It's a good ground, but still to the body. The body-to-battery (or frame or engine) needs to be at least 8 gauge.

Honestly, it's all probably okay. But, there's still room for doubt. For the minimal cost of ensuring your grounds are sufficient, you can ensure the amp won't be starved of power, minimizing its heat and how hard it'll have to work which maximizes its life.

You make me want to Build my own ground straps!!! Im assuming you are making those in house??

What kind of ring terminals are u using?? Care to point me in the direction of your supplies??? That wire loom is sexy too!

Looks like the amp I have installed in my baby. Nice job, looks great.I think that one you were trying with is dual-layered. I don't bother messing with the factory grommets. It's just not worth the hassle or risk of nicking a wire or causing a leak. Bring a piece of your power wire to an auto parts store or hardware store (Home Depot, Lowe's, etc.) and look for a grommet like this:

View attachment 399938

You want one that fits firmly on the jacket of your power wire. Here's mine where I ran it through the floorboard, near one of the right rear seat mounts:

View attachment 399939

I drilled the hole to the OD of the recess in the grommet ("PANEL HOLE DIAMETER" in the following image), cleaned the drilling burrs from around the edge of the hole then painted the metal and let it fully dry. The wire needed a little spritz of lubricant ever so often to slide through the grommet cuz it was a firm fit. Which, is what you want for proper sealing.

View attachment 399947

"OCD" you say?

View attachment 399940

View attachment 399941

Not directly. The seats are bolted to the cab floor, to sheet metal. A circuit needs to have the same ampacity throughout all of its conductors. Otherwise, the ampacity of the smallest (weakest) point will be the circuit's maximum. The battery is grounded to the frame. The body (sheet metal) is grounded to the frame with some rather electrically weak cables. You can ground that amp to sheet metal or to seat frames, etc. that are bolted to the same sheet metal, but that sheet metal needs a matching ground to the frame. So, you'd need an 8 gauge ground from the body's sheet metal to the frame or engine block. I have a 4 gauge ground from the body to the engine block, which is grounded to the frame with 1/0. It's actually the original factory main ground that went from the battery to the engine block, just relocated to the sheet metal:

View attachment 399942

It's a good ground, but still to the body. The body-to-battery (or frame or engine) needs to be at least 8 gauge.

Honestly, it's all probably okay. But, there's still room for doubt. For the minimal cost of ensuring your grounds are sufficient, you can ensure the amp won't be starved of power, minimizing its heat and how hard it'll have to work which maximizes its life.

Looks like the amp I have installed in my baby. Nice job, looks great.