It has been something I've always wanted to do. Not getting any younger - so I'm making it happen.brings back memories!

nice build so far

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My From Start to Finish 6.0L Build

- Thread starter RAMurphy

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

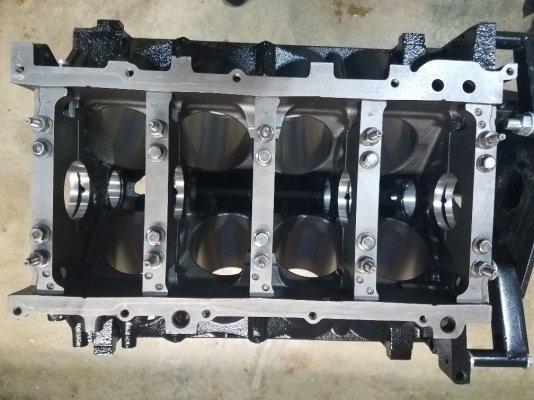

Prior to getting started with the crankshaft install, I weighed all 8 piston rod assemblies and they are all within specs.

Trust but verify completed.

Trust but verify completed.

Last edited:

Just Fishing

Can't fix stupid

It has been something I've always wanted to do. Not getting any younger - so I'm making it happen.

When I did mine, that was my same thought!

Never done one before, and I wanted to try my hand at it.

My 6.0 is amazing, going from a 5.3 I absolutely love it.

tons of low end torque compared to the 5.3

I also used a pretty mild camshaft.

just the stock one from a 6.2 escalade, but I used higher ratio full roller rockers with it.

On that note,

What lifters are you planning to use?

I'm having issues with the "LS7" lifters that everyone loves.

they apparently "flow more oil to the top end".

And for me, it flooded my cylinder heads, and caused lower than expected oil pressures.'

(I'll confirm that soon since I'm planning to swap them out for a different style over the winter)

I also have AFR heads with Pac double valve springs that I believe are part of the issue.

Compressing the lifters too much etc.

Also beware of the factory cam bearings.

Apparently, they don't like high lift and higher than stock valve spring pressure.

Something I might end up swapping out while I have it apart again...

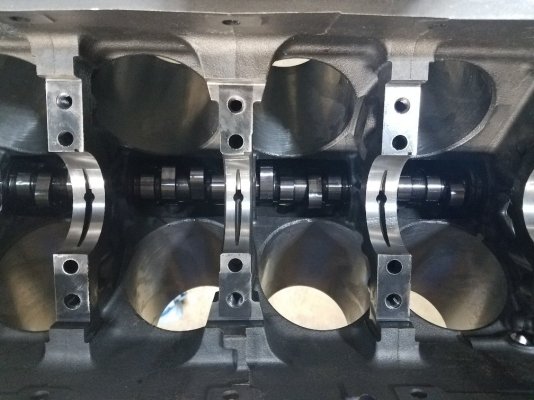

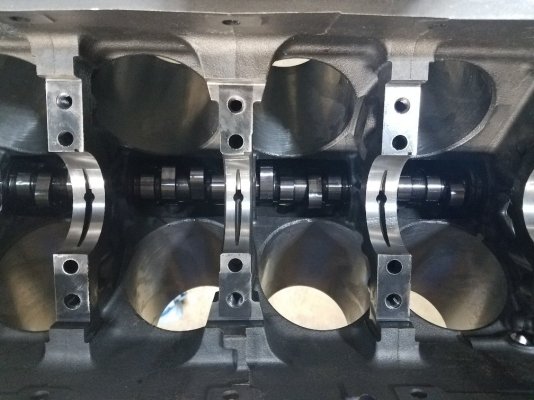

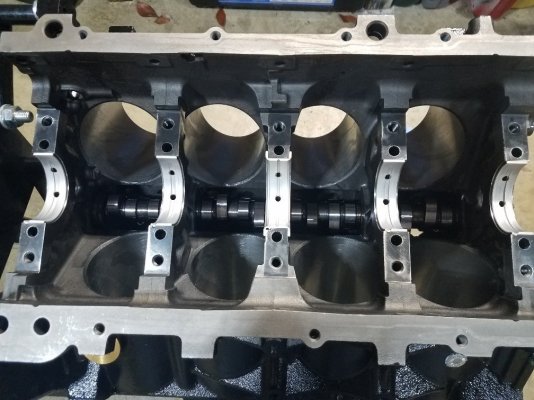

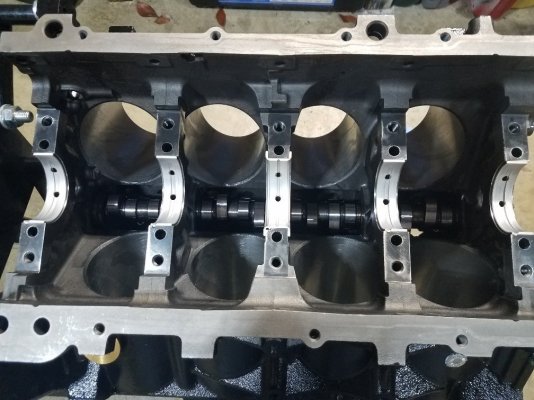

Made some progress today. Cleaned up the block some more and removed the bearing caps. Then did some additional cleaning. Made the decision to install the camshaft at this point and ensured the bearings (non factory bearings were properly lube. Cleaned and fully lubricated the camshaft and then installed it into the block.

Bearing Caps removed:

Camshaft fully cleaned:

Camshaft Installed. I ended up temporarily installing (hand tight) the camshaft cover and timing sproket to keep the camshaft inplace. She rotates very smoothly with no hang up spots.

Bearing Caps removed:

Camshaft fully cleaned:

Camshaft Installed. I ended up temporarily installing (hand tight) the camshaft cover and timing sproket to keep the camshaft inplace. She rotates very smoothly with no hang up spots.

On to the crankshaft. So I needed to first plastigauge my bearings. Installed the bearings:

Cleaned the crankshaft:

Carefully lowered the crank in place:

It was here that I discovered a major problem. I found some major damage to the reluctor ring.

So, obviously this is not good. I called Texas Speed and they also stated that is a problem. They gave me two options. 1. they would send me a new relucter ring and I can have my machine shop replace the damaged one. I already look at that as a possible option, but my guy is on vacation for the next three weeks and he is already backed up. 2. They would provide me a shipping label to ship it back to them for the repair. I went that route. Should get it back early January. I asked if I could continue my bearing check and they said go for it. So I did, sorry no pictures I forgot and quite frankly I was not happy at this point. However, all bearings were at .002. Disassembled the bearing caps, cleaned all bearings surfaces. Pulled the crankshaft. Boxed it up. Placed the shipping label on it and sent it off.

So another delay to the build project.

Cleaned the crankshaft:

Carefully lowered the crank in place:

It was here that I discovered a major problem. I found some major damage to the reluctor ring.

So, obviously this is not good. I called Texas Speed and they also stated that is a problem. They gave me two options. 1. they would send me a new relucter ring and I can have my machine shop replace the damaged one. I already look at that as a possible option, but my guy is on vacation for the next three weeks and he is already backed up. 2. They would provide me a shipping label to ship it back to them for the repair. I went that route. Should get it back early January. I asked if I could continue my bearing check and they said go for it. So I did, sorry no pictures I forgot and quite frankly I was not happy at this point. However, all bearings were at .002. Disassembled the bearing caps, cleaned all bearings surfaces. Pulled the crankshaft. Boxed it up. Placed the shipping label on it and sent it off.

So another delay to the build project.

Tonyrodz

Resident Resident

At least you noticed it before it was too late.On to the crankshaft. So I needed to first plastigauge my bearings. Installed the bearings:

View attachment 387548

Cleaned the crankshaft:

View attachment 387552

Carefully lowered the crank in place:

View attachment 387549

It was here that I discovered a major problem. I found some major damage to the reluctor ring.

View attachment 387550

So, obviously this is not good. I called Texas Speed and they also stated that is a problem. They gave me two options. 1. they would send me a new relucter ring and I can have my machine shop replace the damaged one. I already look at that as a possible option, but my guy is on vacation for the next three weeks and he is already backed up. 2. They would provide me a shipping label to ship it back to them for the repair. I went that route. Should get it back early January. I asked if I could continue my bearing check and they said go for it. So I did, sorry no pictures I forgot and quite frankly I was not happy at this point. However, all bearings were at .002. Disassembled the bearing caps, cleaned all bearings surfaces. Pulled the crankshaft. Boxed it up. Placed the shipping label on it and sent it off.

So another delay to the build project.

Yep, I agree. Sometime you need that reminder to focus on the good and not the bad. Thanks for that reminder.At least you noticed it before it was too late.

Exactly what I'm looking for - low end torque. My camshaft was a custom one from Vinci High Performance to enhance that desire. I will check but I got my lifters from his company. Confirmed the cam bearings are not the factory bearings.When I did mine, that was my same thought!

Never done one before, and I wanted to try my hand at it.

My 6.0 is amazing, going from a 5.3 I absolutely love it.

tons of low end torque compared to the 5.3

I also used a pretty mild camshaft.

just the stock one from a 6.2 escalade, but I used higher ratio full roller rockers with it.

On that note,

What lifters are you planning to use?

I'm having issues with the "LS7" lifters that everyone loves.

they apparently "flow more oil to the top end".

And for me, it flooded my cylinder heads, and caused lower than expected oil pressures.'

(I'll confirm that soon since I'm planning to swap them out for a different style over the winter)

I also have AFR heads with Pac double valve springs that I believe are part of the issue.

Compressing the lifters too much etc.

Also beware of the factory cam bearings.

Apparently, they don't like high lift and higher than stock valve spring pressure.

Something I might end up swapping out while I have it apart again...

George B

¯\_(ツ)_/¯

And, it may be a sign to set it aside until the new year and focus on the season at hand. I find that kind of thing happens to me.Yep, I agree. Sometime you need that reminder to focus on the good and not the bad. Thanks for that reminder.

Similar threads

- Replies

- 3

- Views

- 610