Thank you Mark.Coming together nicely.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My From Start to Finish 6.0L Build

- Thread starter RAMurphy

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

At this point, have you run into any challenges or issues a guy should know about or has it been pretty straightforward?

Mark, I can tell by your build thread that you are a detailed sort of guy and do your research and study. So I don't expect you will have any real issues if and when you do something like this build. I really haven't run into any real issues. I've only ran into two challenges:At this point, have you run into any challenges or issues a guy should know about or has it been pretty straightforward?

1. Installing the wrist pins circle clips. These hold the wrist pins on either end of the pistons. I read that these can be installed without special tools but these people must have biceps in their fingers. I ended up getting a tool, which I mentioned in this build early on. Once I get the tool, it was pretty straight forward have the first piston or two. I sure wouldn't get the plastic tool, it won't last. I could have got my machine shop to do this but I wanted to do the whole build.

2. Second challenge is the willingness to spend money for the necessary tools. Some are one time use tools. I just placed them in a box and will sell them at a later date.

As long as you do the research, have the build books you mentioned earlier, this forum and of course "alldata" it really has been pretty straightforward. At least so far.........

iamdub

Full Access Member

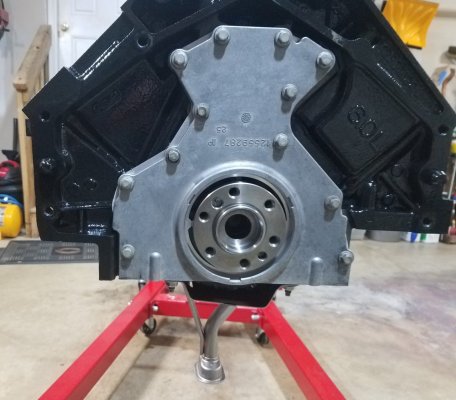

Pulled alignment tool and installed seal.

View attachment 391754

View attachment 391755

Both timing cover and rear cover completely flush with block.

I've never installed a RMS after the cover was on. I've always had the seal in the cover with the donut that guides it and pops out to keep the lips on the seal leaning forward. Did you have any problems keeping the lips aimed properly with this method?

@iamdub I've watched so many videos and it was split almost 50/50 on install. Most people don't want to spend the money on the alignment tools so they proceed the way you mentioned - which is perfectly ok and was the way I was going to go. I reached out to Texas Speed and they stated they use the tool method but they build lots and lots of engines. I decided to go the tool route - so simple and the tool set comes with a u-shaped plate to ensure the cover and oil pan alignment is essentially perfect. As for your question about keeping the lips aimed perfectly - not an issue. By the way, I used your suggestion about the RTV.I've never installed a RMS after the cover was on. I've always had the seal in the cover with the donut that guides it and pops out to keep the lips on the seal leaning forward. Did you have any problems keeping the lips aimed properly with this method?

Spent part of the day looking for an oil pan for this build. Still looking.

Similar threads

- Replies

- 5

- Views

- 189

- Replies

- 38

- Views

- 2K

- Replies

- 9

- Views

- 557