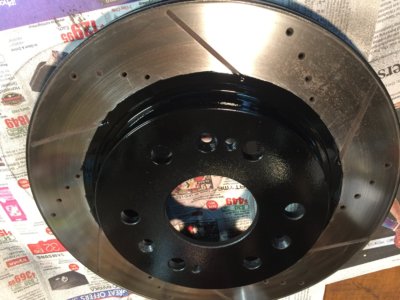

I started on the front brakes today. I was planning on replacing the rotors, calipers, pads and stainless hoses that were originally on The Beast for only a few months when I did my NNBS upgrade. But then I decided to leave the calipers on because they were already black and I have decided I want my brakes to not stand out on this truck, mainly because it has drums on the rear at this point. The ones off The Beast were red. Also, these were in great shape. I do plan on converting to discs in the rear but that will be later. So then I started to replace the stainless hoses but they were different than the Silverado's so that was out. That left me with the rotors and EBC pads. I painted the outer edges of the rotors and thought the hats were covered by the wheels so I didn't paint them. I was wrong but as it was, I only got the left side done today anyway so I'll take it apart and paint that tomorrow. But I was glad I decided to swap the pads and rotors out. The pads he had on it must have been the cheapest made; they had probably 70% left but they had some serious cracks and I have no doubt they would have fallen apart. Plus the rotors are slotted so they might dissipate heat better.