You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your NBS GMT800 Tahoe/Yukon Today?

- Thread starter vwbeaner

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

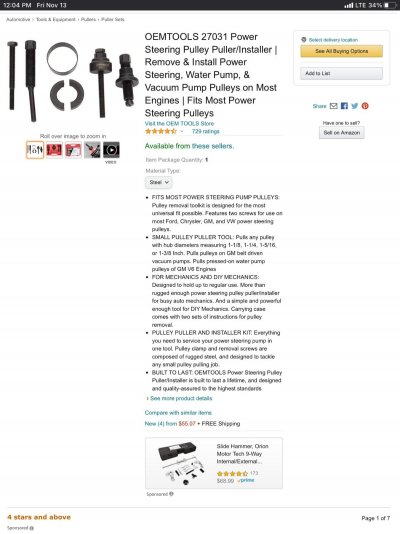

Iirc...3pc jaw & sleeve on the pump, followed by the washer and then puller body with center screw. Then find the one that will screw into pump? It’s been awhile...does anybody know which combination of pieces is used to install the power steering pulley? Getting it off was fun enough ! Here’s the tool I borrowed...the directions are long past being readable.

View attachment 262323

Sent from my iPhone using Tapatalk

live2pull

Full Access Member

I ended up using a strap wrench and i think a 3/8-16 bolt/nut/washer combo

treehan77

TYF Fiend

Care to share how you did it?Finally figured it out. Or at least my way lol. That pump about whipped me, never thought it’d be harder than the pitman/idler/tie rods I did yesterday lol. Was starting to think I might miss my alignment appointment Friday at 8:45

View attachment 262340 View attachment 262341

Dantheman1540

Full Access Member

does anybody know which combination of pieces is used to install the power steering pulley? Getting it off was fun enough ! Here’s the tool I borrowed...the directions are long past being readable.

View attachment 262323

I hate those "do all" kits. I always open them and stare for a good 5 minutes trying to analyze what i need before surrender to the trial and error method.

treehan77

TYF Fiend

As for the pulley removal, I used none of the little adapters, I just used the “center screw” along with the two half moon clamps and the sheath with the “puller body”. Not a lot of working room, with any of the little adapters, I no longer had room to put a ratchet on it. And I needed something with more leverage than my little 1/2” box wrench. Every video I watched showed shroud and fan removal, but I have have e-fans, so I didnt do that, and it was tight. Was able to use a 1/2” socket and ratchet, and a big wrench (21mm?) resting against the frame to pull it off. Putting on, I used the longer screw adapter. Screw it into the center screw, then thread into the pump shaft. Then the position the pulley and then the bearing. The bearing washer was missing from the kit. Then the puller body again. Start muscling it on with the big wrench while holding with the small wrench. I measured with my micrometer the gap of the pulley to the bracket body before I took of the old one, so I’d know when to stop. Since you can’t see when the shaft end is flush with the pulley. Not terribly difficult once I figured out which pieces and how.

Thanks for the follow-up. Kind of sounds like a pain. Would it be easier if you pulled the fans?As for the pulley removal, I used none of the little adapters, I just used the “center screw” along with the two half moon clamps and the sheath with the “puller body”. Not a lot of working room, with any of the little adapters, I no longer had room to put a ratchet on it. And I needed something with more leverage than my little 1/2” box wrench. Every video I watched showed shroud and fan removal, but I have have e-fans, so I didnt do that, and it was tight. Was able to use a 1/2” socket and ratchet, and a big wrench (21mm?) resting against the frame to pull it off. Putting on, I used the longer screw adapter. Screw it into the center screw, then thread into the pump shaft. Then the position the pulley and then the bearing. The bearing washer was missing from the kit. Then the puller body again. Start muscling it on with the big wrench while holding with the small wrench. I measured with my micrometer the gap of the pulley to the bracket body before I took of the old one, so I’d know when to stop. Since you can’t see when the shaft end is flush with the pulley. Not terribly difficult once I figured out which pieces and how.

treehan77

TYF Fiend

Yes. But I decided I didn’t want to mess with it. Just more work, most of my time was spent making damn sure I wasn’t gonna damage pulley by doing it wrong, or worse, damaging the new pump shaft when installing it again. Pitman, idler and tie rods I did pretty good, seemed to track straight without pulling on the way to the dealer for alignment. Steering wheel was at 1230 thoughThanks for the follow-up. Kind of sounds like a pain. Would it be easier if you pulled the fans?

dubyagee01

Full Access Member

- Joined

- Nov 17, 2015

- Posts

- 301

- Reaction score

- 366

Similar threads

- Replies

- 2

- Views

- 486