Ah, the joys of using new or louder curse words and having a neighbor hear them and then days later asking what "THAT" was all about. Then you ask them, "Do you have some time while I relate to you why all that came about". I am looking forward to you being done and hopefully sharing lots of pics along the way.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear Main Oil Seal

- Thread starter Larryjb

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

I'm probably not going to take many pictures for this job. There are plenty of videos and other pictures for the basics, but what there is not much of is a nice list of steps complete with socket sizes. It's really nice when I find some one who has taken the time to document what socket size he used.

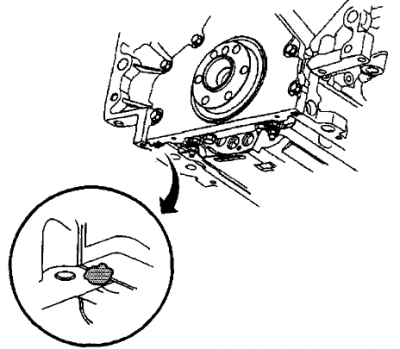

I'll take a couple of pictures of anything interesting for sure. One thing that is not well pictured anywhere is the location of where to put the oil-resistant RTV.

I'll take a couple of pictures of anything interesting for sure. One thing that is not well pictured anywhere is the location of where to put the oil-resistant RTV.

It’s at the 2 spots in the front and 2 spots in the back where the front cover and rear main cover intersect the pan, there’s a gap there.I'm probably not going to take many pictures for this job. There are plenty of videos and other pictures for the basics, but what there is not much of is a nice list of steps complete with socket sizes. It's really nice when I find some one who has taken the time to document what socket size he used.

I'll take a couple of pictures of anything interesting for sure. One thing that is not well pictured anywhere is the location of where to put the oil-resistant RTV.

I knew Rocket Man would be all over this answer. He posted the same file in another thread. Plus, it answers all questions concerning the sealer locations. Great call.

By the way, Larry, can you please record the audio during the work process for any new curse words with the Canadian accent?

By the way, Larry, can you please record the audio during the work process for any new curse words with the Canadian accent?

Last edited:

Thanks Rocket Man,

I did manage to figure that out without pictures, but that is a nice drawing to confirm what is necessary.

I got the pan out very easily. Rickafix has a nice video which covers the basics. He said he struggled for a 1/2 hour or an hour to wrestle the pan out. 10 minutes of removing those axle-differential bolts and letting the differential sit on the center link and mount bracket gave me enough room to just about slide the whole thing out in about 2 minutes. Plus, there is no strain on the CV joints. Of all the unnecessary things I did, I would not consider separating the diff unnecessary. It helps a lot with space.

If you look back in my previous threads, you will see a thread about a cracked non-Castech head, and oil sludge. I've been using Valvoline synthetic for the last 2 years. Although my oil filter didn't get clogged up these last 2 years, and the oil drained easily, and I've had decent oil pressure, there was a good inch of sludge in the bottom of the pan. I'll be spending the better part of today cleaning that all up.

Of yesterday's 4 hours, probably a good 45 minutes was spent cleaning sludge from the cross member. It was so gross, and I really didn't like the idea of that sludge falling into my face while trying to reinstall the thing. As it was, I almost ate some sludge that fell off the front of the oil pan.

And yes, I am considering the possibility that the front timing cover may be leaking too, but I want to take care of oil pan leak first. If the timing cover seal needs replacing, there's a whole ton of stuff to come off for that one.

On a side note, while the transmission jack is working fine, and is very useful to lift and manage the differential, it came without enough hydraulic oil. I had to add quite a bit before it would lift up to the full height. Even after that, I had to bleed it several times as well. But so far, it is very nice to use. This one is by PowerFist,

I did manage to figure that out without pictures, but that is a nice drawing to confirm what is necessary.

I got the pan out very easily. Rickafix has a nice video which covers the basics. He said he struggled for a 1/2 hour or an hour to wrestle the pan out. 10 minutes of removing those axle-differential bolts and letting the differential sit on the center link and mount bracket gave me enough room to just about slide the whole thing out in about 2 minutes. Plus, there is no strain on the CV joints. Of all the unnecessary things I did, I would not consider separating the diff unnecessary. It helps a lot with space.

If you look back in my previous threads, you will see a thread about a cracked non-Castech head, and oil sludge. I've been using Valvoline synthetic for the last 2 years. Although my oil filter didn't get clogged up these last 2 years, and the oil drained easily, and I've had decent oil pressure, there was a good inch of sludge in the bottom of the pan. I'll be spending the better part of today cleaning that all up.

Of yesterday's 4 hours, probably a good 45 minutes was spent cleaning sludge from the cross member. It was so gross, and I really didn't like the idea of that sludge falling into my face while trying to reinstall the thing. As it was, I almost ate some sludge that fell off the front of the oil pan.

And yes, I am considering the possibility that the front timing cover may be leaking too, but I want to take care of oil pan leak first. If the timing cover seal needs replacing, there's a whole ton of stuff to come off for that one.

On a side note, while the transmission jack is working fine, and is very useful to lift and manage the differential, it came without enough hydraulic oil. I had to add quite a bit before it would lift up to the full height. Even after that, I had to bleed it several times as well. But so far, it is very nice to use. This one is by PowerFist,

Now that I'm working to clean the gasket surfaces, having the differential out completely would have been a big help. One more nut holding the center link to the pitman arm is all it would have taken. Alas, I've done most of the work now, so I'll leave it as it is.

I'll post a picture later, but the machining of the gasket surface on the pan is quite poor. There is a ridge crosswise alone the mating surface. When I install the pan I'll add a tiny smear of RTV in that location. The RTV from the rear main cover and the front cover bulged below the mating surface on the block. I used a razor to even it with the mating surface. That's where a new dab of RTV will go anywway.

So was my pan the only one machined so poorly? Or did no one else notice it on theirs? I'm close to putting things back together. I only have to install the new o-ring and finish cleaning the gasket surface of the block.

I'll post a picture later, but the machining of the gasket surface on the pan is quite poor. There is a ridge crosswise alone the mating surface. When I install the pan I'll add a tiny smear of RTV in that location. The RTV from the rear main cover and the front cover bulged below the mating surface on the block. I used a razor to even it with the mating surface. That's where a new dab of RTV will go anywway.

So was my pan the only one machined so poorly? Or did no one else notice it on theirs? I'm close to putting things back together. I only have to install the new o-ring and finish cleaning the gasket surface of the block.

Separating that Pitman arm is way harder than removing the nut. If you’ve ever replaced one you would know. Pulling a differential so you can scrape a gasket better is crazy imo! I had no problem cleaning mine up. My pan surface wasn’t machined poorly at all. Maybe your pan has been replaced with an aftermarket? Did it have 2 pop rivets holding the gasket on? I reinstalled those on mine, some don’t but it sure helps hold the gasket in place when putting the pan in.

Edit: after reading again I see you weren’t talking about pulling the Pitman arm but still... good to see you’re making good progress though!

Edit: after reading again I see you weren’t talking about pulling the Pitman arm but still... good to see you’re making good progress though!

Pulling the differential completely out would not be much more work than what has already been done. Most pull the 4 bolts holding the differential in, disconnect the electrical connector, and vent hose. The two long bolts supporting the differential in the mounts are the most difficult by far. It was 10 more minutes to mark and separate both axles. After that it's just the center link.

There are more reasons than to scrape the gasket that pulling the differential makes sense for. Dropping the oil pan is dead easy with the differential completely out. It was easy enough when the differential resting on the center link already. Furthermore, aligning and torquing the oil pan bolts will be much easier and more accurate with the diff out. The use of swivel joints to get the pan bolts above the diff will change the torque. Hopefully not by much, but it will change it.

Here's a picture of my oil pan:

My pan is definitely original and the gasket was held in place with the rivets. This could have been the leak all along. This is not a score or gash. The two sides are actually different heights. I'll smear a thin coat about 2 inches on either side of this point.

There are more reasons than to scrape the gasket that pulling the differential makes sense for. Dropping the oil pan is dead easy with the differential completely out. It was easy enough when the differential resting on the center link already. Furthermore, aligning and torquing the oil pan bolts will be much easier and more accurate with the diff out. The use of swivel joints to get the pan bolts above the diff will change the torque. Hopefully not by much, but it will change it.

Here's a picture of my oil pan:

My pan is definitely original and the gasket was held in place with the rivets. This could have been the leak all along. This is not a score or gash. The two sides are actually different heights. I'll smear a thin coat about 2 inches on either side of this point.

I knew Rocket Man would be all over this answer. He posted the same file in another thread. Plus, it answers all questions concerning the sealer locations. Great call.

By the way, Larry, can you please record the audio during the work process for any new curse words with the Canadian accent?

Simple, no audio required:

%#^!@ sounds like %#^!@-eh

and

*$@&^* sounds like *$@&^*-eh

French Canadian accents just add tabernacle just before the "eh".

LmaoSimple, no audio required:

%#^!@ sounds like %#^!@-eh

and

*$@&^* sounds like *$@&^*-eh

French Canadian accents just add tabernacle just before the "eh".

Similar threads

- Replies

- 32

- Views

- 3K